Slaughter equipment refers to a range of specialized machinery and tools used in the meat processing industry to humanely and efficiently slaughter animals for food production. This equipment is designed to ensure animal welfare, improve hygiene, and enhance the efficiency of the slaughtering process. It is widely used in abattoirs, meatpacking plants, and poultry processing facilities.

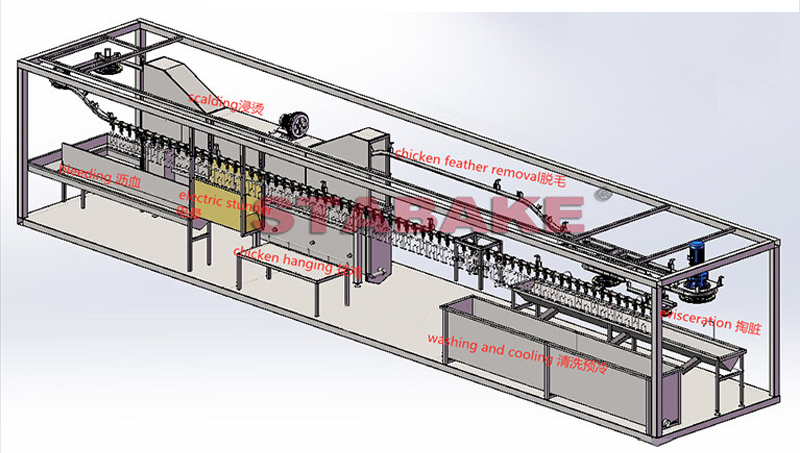

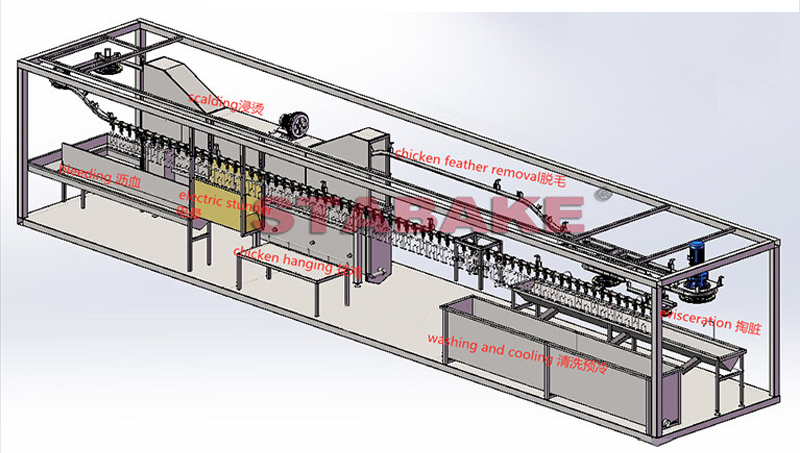

Process flow: Hang an electric hemp on the broiler chicken, slaughter, drain blood, soak and scald, depilate, dig out the chamber, grade, grade, pre cool, drain, divide, pack, and store.

Equipment used: drain pool, soak and scald pool, depilatory machine (vertical depilatory machine, head force depilatory machine, horizontal depilatory machine can be combined according to production), wax immersion pool, dewaxing pool, wax stripping machine, automatic head cutting machine, claw cutting oil machine, claw ironing machine, automatic claw peeling machine, spiral pre cooling machine, peeling machine, segmentation molding machine, poultry body lifting conveyor, etc.

Modern slaughter equipment is designed with a focus on automation, precision, and compliance with food safety regulations. Many systems are equipped with advanced features like automated controls, sanitation systems, and waste management solutions to ensure cleanliness and reduce contamination risks. Additionally, the equipment is often made from durable, corrosion-resistant materials to withstand harsh cleaning processes and prolong its lifespan.

The use of slaughter equipment not only improves the efficiency and safety of meat processing but also ensures compliance with animal welfare standards and food safety guidelines.