Food Application

About Pizza production and Solution

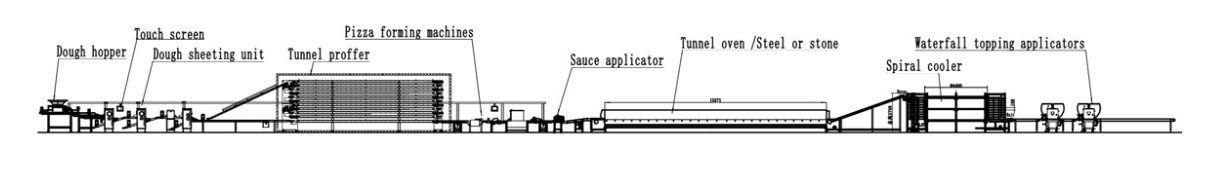

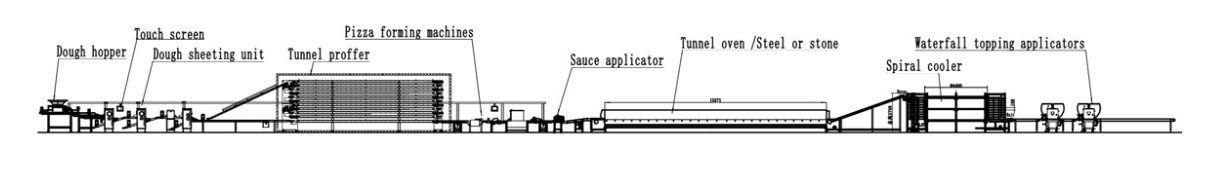

About the automatic pizza production solution, StaBake offers you equipment and consulting service includes dough preparation, pizza base forming; proofing; baking; sauce smearing, cheese and various toppings spreading, packing and freezing machines. Pizza production usually have 3 solutions:

Pizza base production line solution;

Frozen pizza production line solution;

Baked pizza production line solution

According to pizza type you make and situation, our engineers will provide professional solution and consulting service on production line planning, such as factory layout design, different machine combination in order to helping you build the industrial pizza production line and start up your business successfully.

In the solution below is the pizza complete line machines which can make frozen pizzas smeared with sauce, cheese and various toppings. The automatic working from dough mixer to last packing and evening freezing, and these machines can be adjusted in model and quantity according to customers’ production capacity needs. Please contact us or fill the form to get more specification and quotation.

Production processing

Dough hopper- Dough Pressing Set- Pizza Base Forming (flour spraying, punching, rotary cutting, dough scrap returning) - Proofing/ Rest Station - Tunnel Oven- Spiral Cooling Tower- Sauce Spreading and Cheese Sprinkling - Toppings Spreading- Aligning system - Package machine

Machine Specification

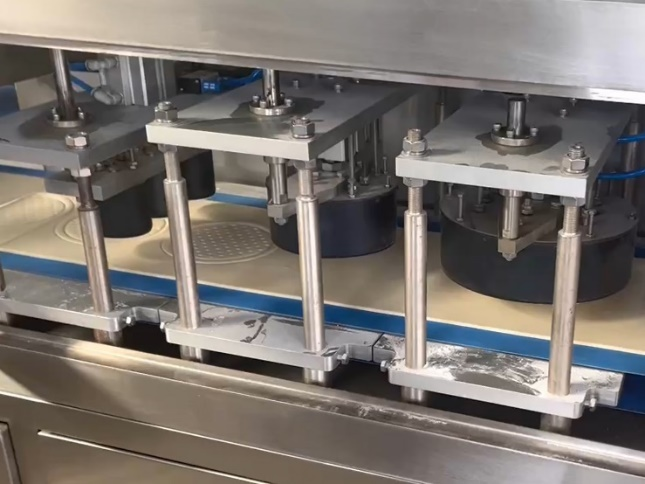

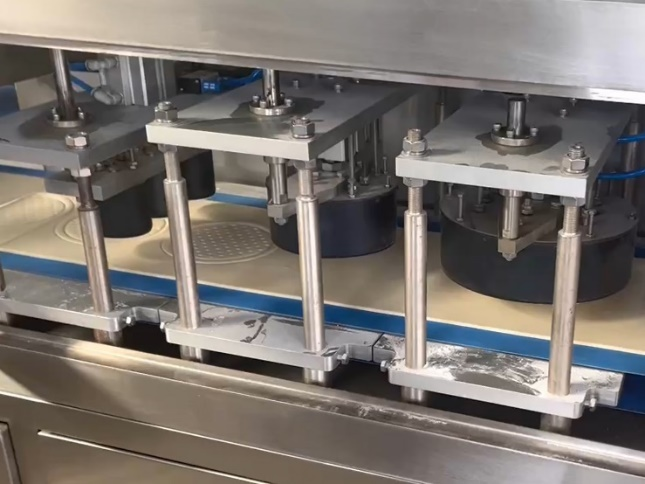

1. Pizza Base Forming Machine

StaBake provides two types of pizza forming machine, designed with a mold cutting and stamping cutting. Both machines’ cutting molds can be adjustable to produce round flatbreads in many different size and different shapes of round, square, rectangular to meet customers’ requirement.

|  |

Rotary Mold Cutting | Stamped Cutting |

2. Proofing Room

Fermentation/proofing is one of the most important processing part of pizza production. StaBake provide the belt proofer and spiral proofer as alternative according to customer factory space. The proofer can be with humidification and heating function or without (as a rest station). And proofer size is designed as per the proofing time request.

|  |

Belt Proofing | Spiral Proofing |

3. Tunnel oven

The tunnel oven is needed for the whole automatic working of the pizza base forming line, 100% to save work labor, improve the production capacity and final product quality. Baking time and temperature is adjustable on the control system. And the tunnel oven size is designed as per the production capacity request.

4. Cooling Machine

The cooling machine is the last part for the pizza base production line. StaBake offer the Spiral cooling tower or cooling conveyor with fans as per request. The spiral cooling tower width is designed based on cooling time requirement and with less space needed. the tower width is designed based on the pizza size and quantity to make. And if with less budget request, we suggest use the cooling conveyor with fans, it is easy working and convenient to connect the Aligning system and packing machine.

|  |

Spiral cooling towe | Cooling conveyor with fans |

5. Sauce, Cheese and Toppings Spreading

StaBake’s fully automatic pizza spreader and cheese machine can realize the complete automation of a series of operations such as the delivery of pizza dough, the application of sauce, and the spreading of cheese. It can accurately control the amount of sauce and cheese, the location and thickness of the application and spreading according to the preset procedures and parameters. Improve efficiency and save labor costs.

|

Pizza Sauce, Cheese and Toppings Spreading Machine |

6. Package

The packing machine with constant temperature heating sealing and cutting system can be used to seal and cut various industrial standard heat-sealed films such as PE, PVC, POF, etc. The seal is firm and beautiful, especially suitable for POF sealing and cutting. When changing the product size, you only need to make simple adjustments through the hand wheel without replacing any parts, which reduces the product replacement time and is easier to operate. The adjustable speed front feeding system and the storage work platform at the back make the whole machine truly realize high-speed, unmanned and automatic operation.

|

Pizza Heat shrink wrapping machine |

How it Work?