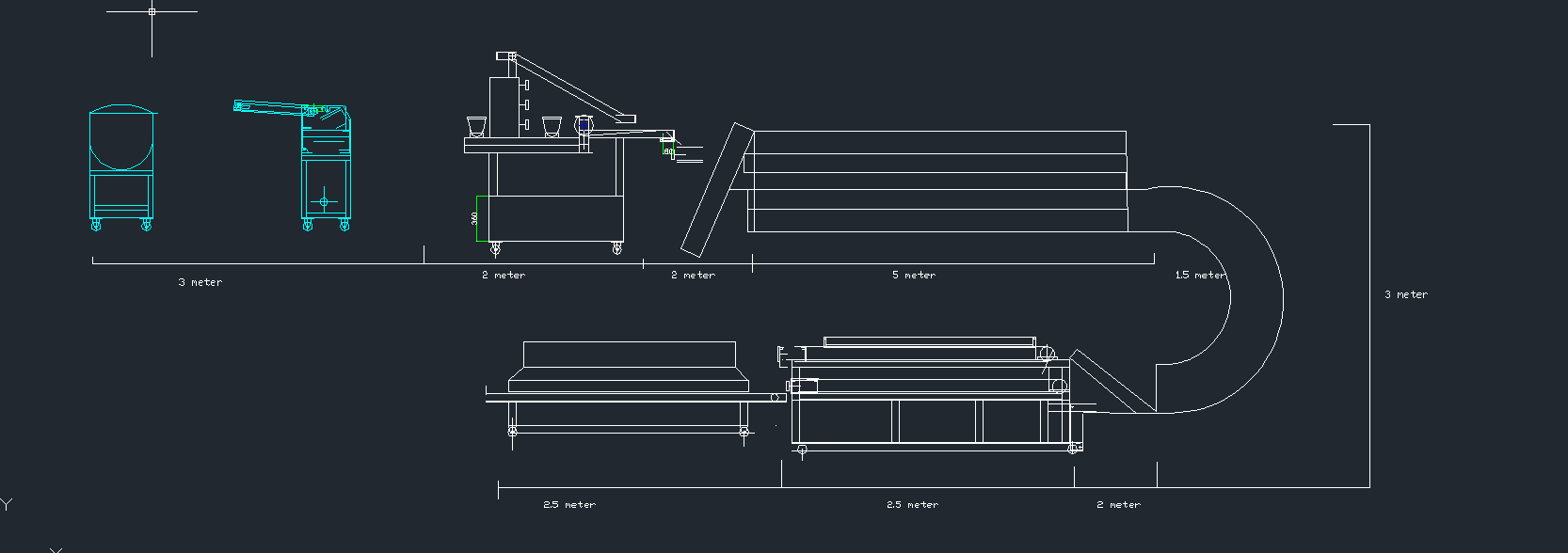

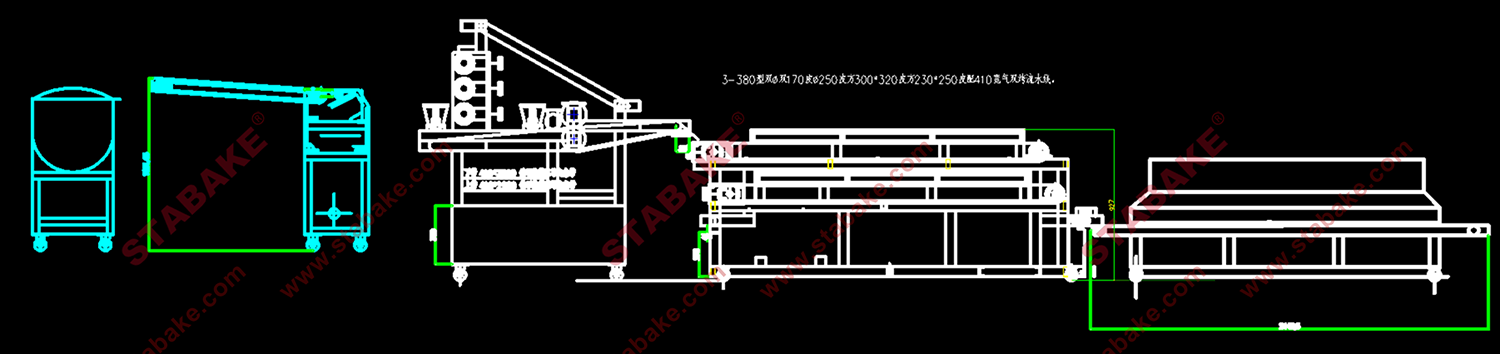

Complete Pita Bread Production Line Solution

Food Application

About Pita bread production and Solution

Pita Bread are a type of pocket flatbread that originated in Middle Eastern and now are popular in the global. There are several types of pocket flat bread: Pita bread, Arabic bread, Turkish Puff bread, Lebanese Bread, Egyptian Bread, Roti chapatti bread etc . Pita bread can be used in a variety of dishes, including: Sharwarma, beef pita sandwiches, falafel pita, lebanese falafel, Pita bread tacos etc.

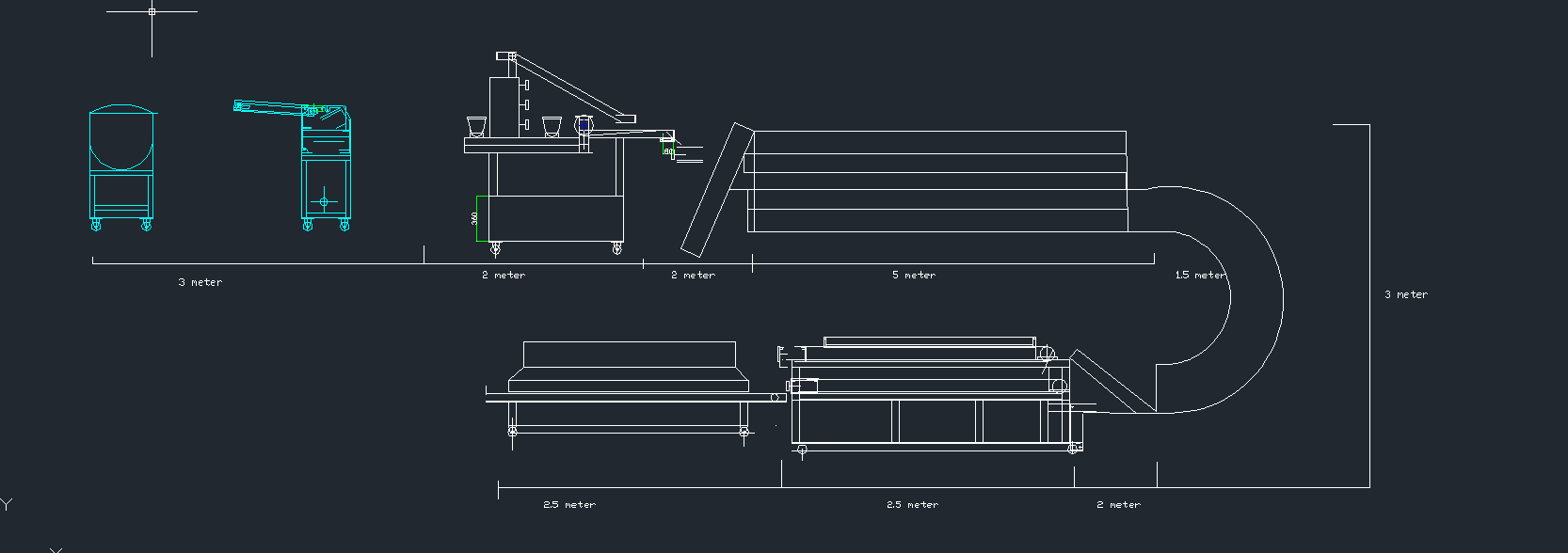

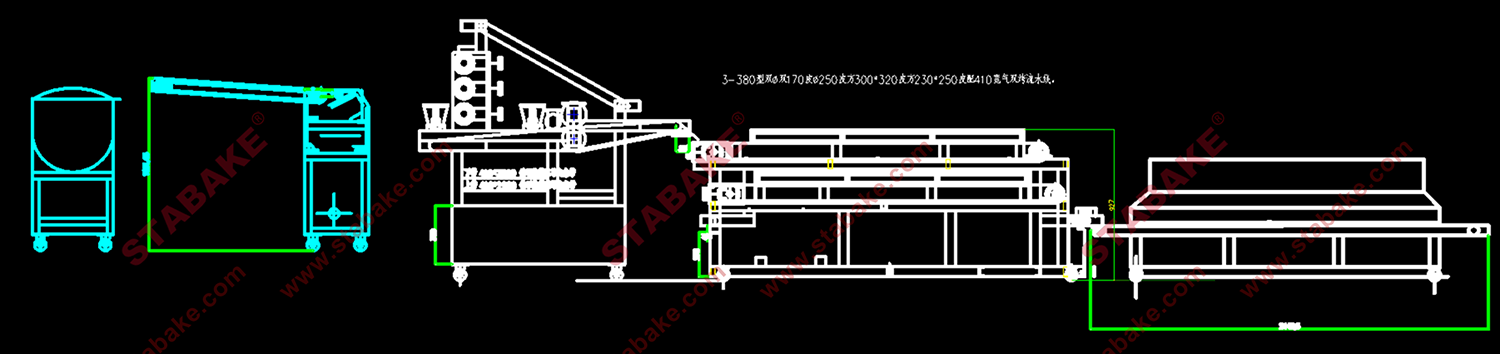

Pita bread have been produced for centuries and have become popular around the globe. As the need of high-capacity demand, the traditional production method has couldn’t meet the market requirement. StaBake offers the automatic production method including equipment of dough divider; proofing, baking; cooling and packing machine. And our engineers will provide professional solution and consulting service on production line planning, such as factory layout design, different machine combination in order to helping you build the industrial tortilla production line and start up your business successfully.

In the solution below is the pita bread complete production line machines which can make the pita bread from dough mixer to last packing, and these machines can be adjusted in model according to customers’ production capacity needs. Please contact us or fill the form to get more specification and quotation.

Production Processing

Dough Mixing – Dough Rolling – Dough Shaping – Dough Proofer – Baking – Cooling – Stacker – Packing

Flow Chart:

Machine Specification

1. Dough Rolling Machine

StaBake provides the simi-automatic dough roller machine, automatic dough roller machine, continuous dough rolling machine. You can combinate the suitable roller machine according to your requirement and budget.

|  |  |

| Simi-automatic dough rolling | Automatic dough rollin | Continuous dough rolling |

2. Pita Bread Forming Machine

The pita bread forming machine is the first essential machine of pita bread production line. StaBake provide the two types of pita bread forming machine, designed with a mold cutting and stamping cutting. Both machines’ cutting molds can be adjustable to produce flatbreads in many different size and different shapes of round, square, rectangular to meet customers’ requirement.

|  |

Rotary Mold Cuttin | Stamped Cutting |

3. Proofing Room

Fermentation/proofing is one of the most important processing parts of pita bread production. StaBake provide the belt proofer and spiral proofer as alternative according to customer factory space. The proofer can be with humidification and heating function or without (as a rest station). And proofer size is designed as per the proofing time request.

|  |

Belt Proofin | Spiral Proofing |

4. Tunnel oven

The tunnel oven is the second essential machine of the whole automatic working of the pita production line. Baking time and temperature is adjustable on the control system. And the tunnel oven size is designed as per the production capacity request and can be produced with single layer or double layer as request.

|

Tunnel oven |

5. Cooling Machine

The cooling machine is the last part for the pita bread production line. StaBake offer the Spiral cooling tower or cooling conveyor with fans as per request. The spiral cooling tower width is designed based on cooling time requirement and with less space needed. the tower width is designed based on the pizza size and quantity to make. And if with less budget request, we suggest use the cooling conveyor with fans, it is easy working and convenient to connect the packing machine.

|  |

Spiral cooling towe | Cooling conveyor with fans |

Feature:

Various application products of Pita bread, Arabic bread, Lavash bread, Tortilla, Roti, Chapati, Lebanese bread, Egyptian bread etc.

Flexible machine configuration and manufacture to solve customers’ production needs

Customize design and manufacture according to different bread and different capacity requirement.

Machine Test Service provide according to customer’s formula to reduce the risk of machine working.

Small Pita Bread Production Line Solution

Working Process:

Specification of Production Process Machine (DBJ-500 model):

Technical Parameter:

NO. | Equipment name | Dimension | Power |

1 | Horizontal Dough Mixer with Lift Conveyor | 1500*1000*1300mm | 5.5kw |

2 | Automatic Dough Roller | 1600*1000*1500mm | 4kw |

3 | Double Layer Conveyor | 2500*600*1400mm | 3.5kw |

4 | Dough Pressing Machine | 2000*1000*1500mm | 2.2kw |

5 | Dough Forming Machine | 1900*880*1110mm | 2.2kw |

6 | Tunnel Oven | 2650*950*1020mm | 0.12kw |

7 | Cooling Machine | 2400*1080*780mm | 0.75kw |

1. Horizontal dough mixer

Power: 2.2 KW/380V/50HZ/3PH

Capacity: 50KG/batch

Dimension: 1010*590*970mm

Advantage:

Two type Stirrer (alternative) for hard or soft dough

Mixing bowel and Stirrer SS304 Stainless steel

2. Automatic Dough roller machine

Power: 3KW/380V/50HZ/3PH

Capacity: 900kg per hour

Dimension: 1300*770*1130mm

Advantage:

Belt anti-deviation device

304 Stainless steel roller set

Roller quantity: 3pcs

3. Bread Forming machine

Power: 2.2KW/220V/50HZ/1PH

Capacity: 500-8000Pcs/H(Based on product size)

Dimension:1900*880*1110mm

Advantage:

three pairs stainless less roller set

With efficient dough feeding plate

Thickness adjusting handlewheel with scale

Mold shape and size customized

Frequency speed adjusting for belt and roller

4. Tunnel oven

Capacity: 500-4000PCS/H(Based on product size)

Heating source: Gas or Electric

Temperature: 0-400℃Adjustable

Dimension: 2650*950*1020mm

Advantage:

Single or Double layer Customized

Length and width customized

5. Cooler

Power: 0.75KW/220V/50HZ/1PH

Capacity: Equipped with Oven output

Dimension: 2400*1080*780mm

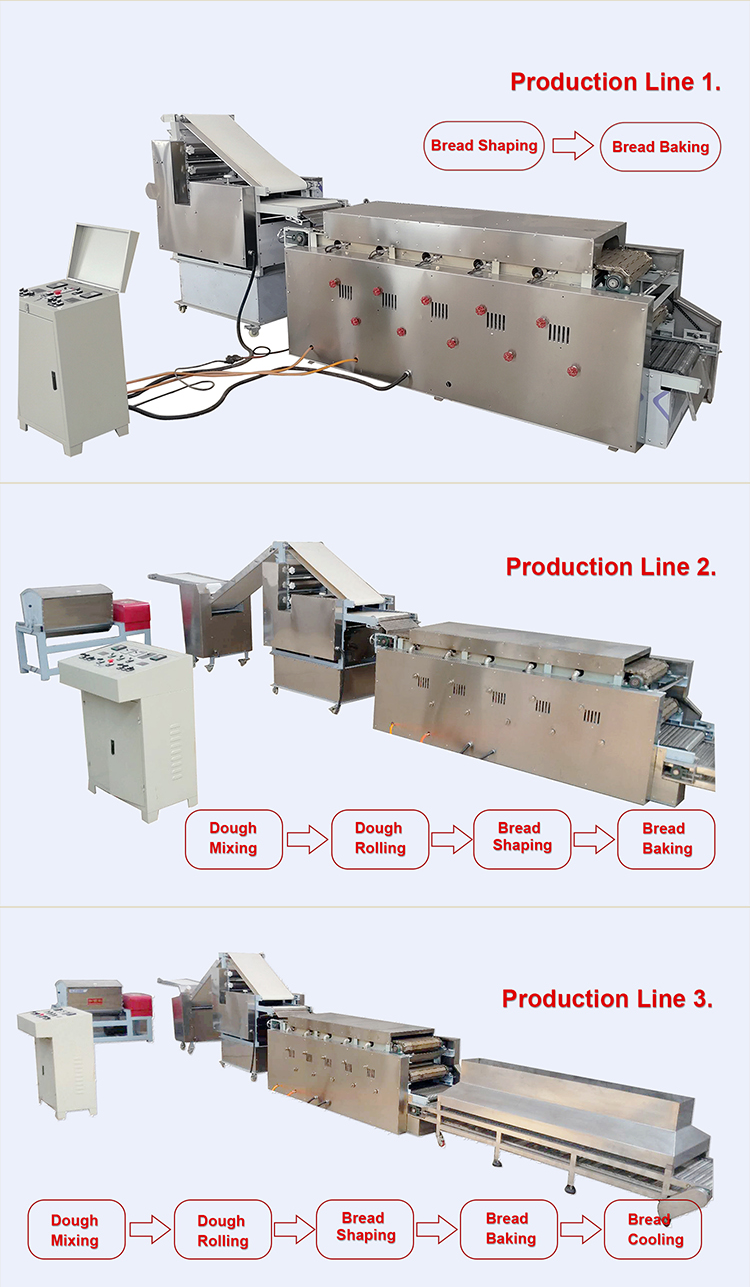

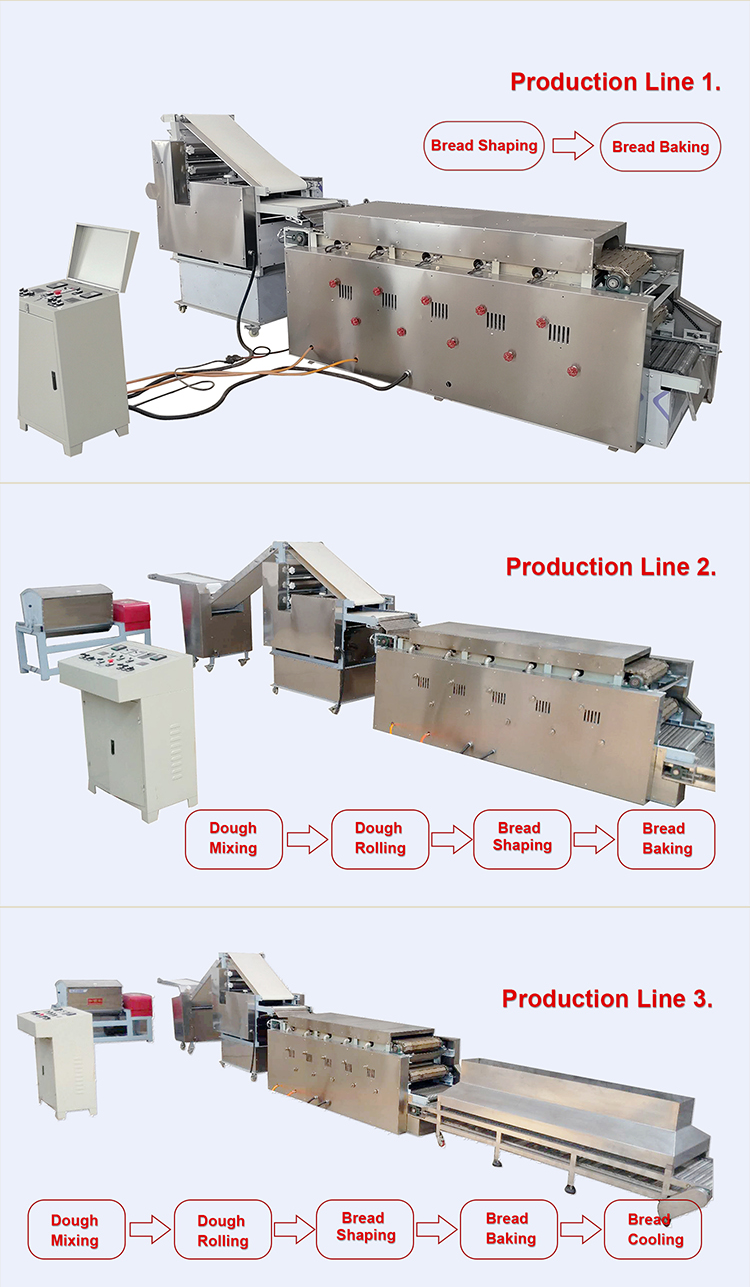

Several Popular Production Line Sample: