About Frozen French Fries Production Line

|  |

Frozen French fries' production line is a complete line from raw material selection, blanching, peeling, cutting, frying, cooling, freezing, packaging, and storage.

The raw materials for frozen French fries production line mainly is potatoes, sweet potatoes, cassava. The first step is to select high-quality raw materials and clean them. Then the raw materials are blanched and peeled. After that, the raw materials are cut into French fry shapes and then fried.

Frying is a key step in the production of frozen French fries. The temperature and time of frying are crucial factors that affect the quality of French fries. The fried French fries are then cooled down rapidly to room temperature in a cooling chamber.

After cooling, the French fries are placed in a freezing tunnel where they are frozen quickly to -18℃ or lower. This rapid freezing process helps to retain the texture and flavor of the French fries.

Finally, the frozen French fries are packed into bags or boxes for sale. The packaging materials should be impermeable to moisture and oxygen to ensure that the French fries remain fresh and crispy for a long time.

In conclusion, the frozen French fries production line is a highly automated and efficient production line that produces high-quality frozen French fries in large quantities.

|  |

Frozen French fries Production Process Analysis

1. Process Flow:

Fresh Potato transport into Brush peeling machine for peeling and washing

Peeled potatoes through picked line transport into cutting machine for cutting sliver

Potato sticks convey into bubble washing machine to washing off starch

Through 60-95 degree hot water blanching to protect potato sliver color

Convey into Continous frying machine for frying the potato slivers

After air cooling and convey into freezing machine for quick freezing

Automatically pack potato strips into plastic bags

2. Flow Chart:

Prewashing feeding machine — Washing and peeling machine — Picking line — Cutting machine — lifting machine — Rinsing machine — Blanching line — Vibrating screen — Air-dryer dewatering line — Continuous Frying machine — Vibrating screen — Air-dryer deoiling machine — Quick-frozen machine(Seasoning mixing)— Automatic packing machine — Finished product — Cold storage.

Frozen French fries Production Main Machine

1. Potato Peeling Machine

|  |

Brush Roller peeling machine (capacity: 1-3ton per hour | Steam peeling system (capacity: 3-12ton per hour) |

2. Fries Cutter Machine

|  |  |

America model (3000kg/h) | Taiwan Model (600-800kg/h | Hydro cutter (3000-6000kg/h) |

3. Hot Water Blanching Machine

Heating type: 1. Electric heating 2. Built-in burner heating, 3. Steam heating

Types: Belt blanching and Screw blanching, blanching temperature is about 85-90℃, 3 minutes.

4. Continuous French fries Frying machine

Heating type: 1. Electric heating 2. Built-in burner heating, 3. External gas heating, 4. Steam heating

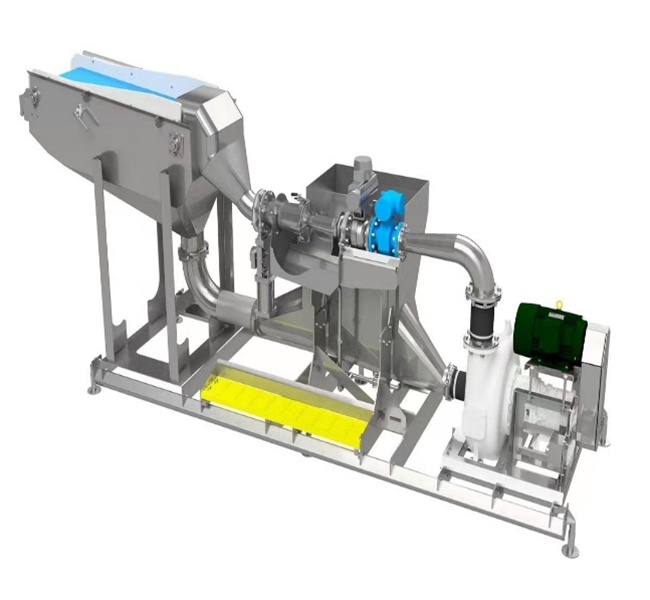

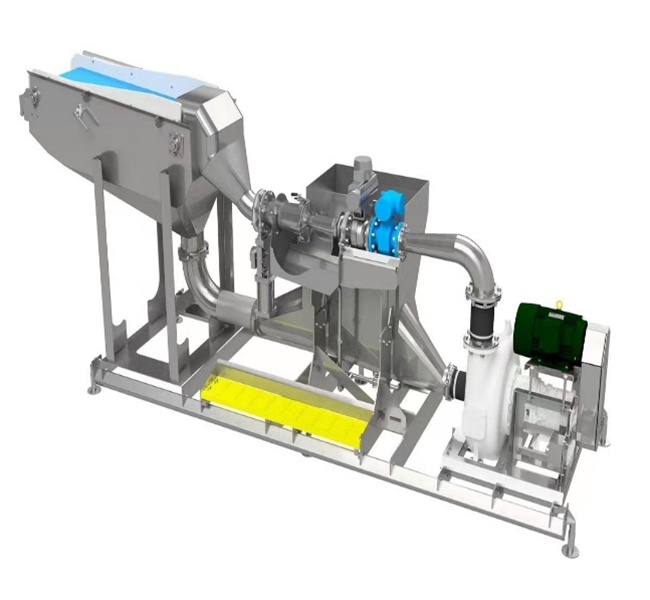

5. Tunnel Fluidization Quick Frozen Machine

STABAKE fluidized single quick freezer is an efficient quick freezing device for French fries. Through mechanical vibration and wind pressure, the product floats on the stainless steel mesh belt to form a fluid-like state, thereby achieving rapid freezing of the single piece and preventing adhesion.

6. Automatic packing machine

Frozen French fries Production Line working video:

Installation & Commission:

1) Guide Installation:

The supplier provide guidance service online or telephone for installation and commissioning within 48 hours after receiving the notice from the buyer.

2) Technician to the Site Installation:

we shall send one engineer to the buyer’s location for installation, commissioning, and training for 7 days. The buyer shall pay for the salary, round-trip tickets, visa application expense, (including round-trip tickets for visa), food and hotel (with internet available), security, traffic at buyer’s site. The salary is USD150/Day (7hours) for this engineer (From the date of our departure to return to my company).

The buyer should supply the support steel frame, installing tools and others required during in the installation and commissioning.

3) Operator Training:

Equipment from the wiring, debugging, the buyer side operators will be under the guidance of the supplier, learning the mechanical working principle and maintenance factors of the operation processing, master the use of equipment theory and practical experience.