Pizza processing project making pizza from A to Z

Description

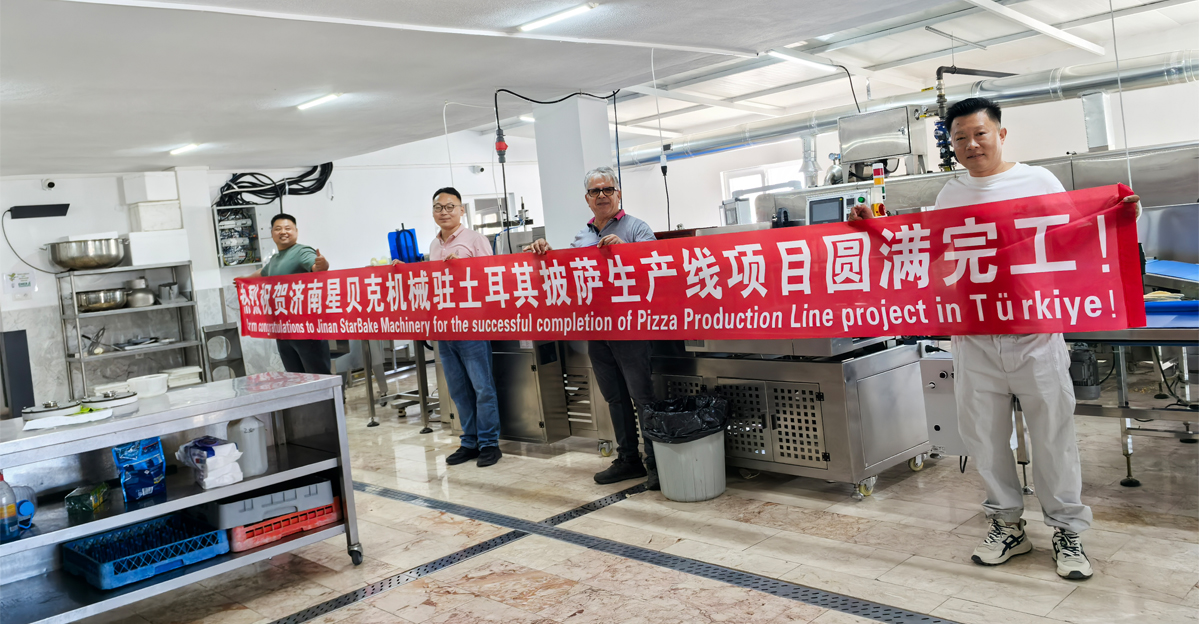

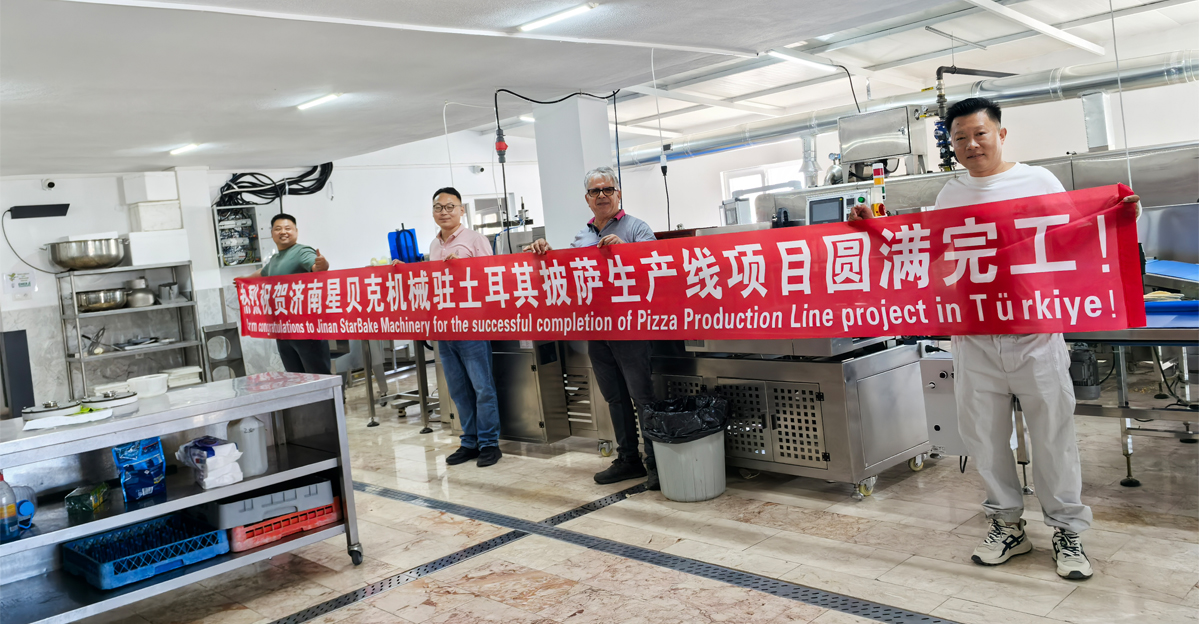

The Pizza Production Line: From Dough to Delivery was installed In Turkey.

A modern pizza production line is a fascinating and highly efficient process that transforms raw ingredients into the beloved finished product. Whether for a large frozen pizza brand or a high-volume food service provider, the line follows a series of precise, automated steps.

Here is a breakdown of the typical stages:

1. Dough Preparation and Mixing

The process begins with thedough station. Pre-measured ingredients like flour, water, yeast, salt, and oil are loaded into large, industrial mixers. These mixers knead the ingredients into a consistent, uniform dough.

2. Dough Dividing and Pizza modling

The large mass of dough is then transferred to a pizza base maker. This step is crucial for creating the perfect pizza.

3. Proofing

The pizza base are placed on conveyor belt go to next step: yeasting, or called proofer.This is a warm, humidified chamber where the dough is allowed to rest and rise. The yeast ferments, causing the dough to become light and airy, developing its characteristic texture and flavor.

4. Baking

The pizzas then enter a massive,continuous oven. These are typically tunnel ovens with a conveyor belt moving through them. They can be powered by gas, electricity, or infrared heat and can reach very high temperatures. The pizzas bake for a specific, controlled time (usually 1-5 minutes) until the pizza base get into hard and the crust is littte golden.

5. Sauce Application

The bare crusts move along a conveyor belt to thesaucing station. An automated dispenser, through the tracking system, the sauce was accurately sprinkled into the center of the pizza

6. Cheese and Topping Application

This is often the most complex stage:

· Cheesing: A shredder discharges a uniform layer of cheese (typically mozzarella) over the sauced crust.

· Topping: For automated lines, vibratory dispensers or portion-controlled "guns" accurately place toppings like pepperoni, sliced vegetables, and meats. For more delicate or complex pizzas, this step might still involve manual placement by workers along the line.

7. Cooling

Directly after baking,the hot pizzas must be cooled quickly to stop the cooking process and prevent sogginess. They travel through a cooling tunnel, where ambient or chilled air is blown over them. This step is critical for food safety and quality, especially for frozen pizzas.

8. Packaging and Labeling

Finally,the pizzas reach the packaging station.

· Fresh/Frozen: For frozen pizzas, they are quickly flash-frozen, then wrapped in plastic film and placed into cardboard boxes.

· Fresh-Chilled: For fresh delivery, they are boxed directly.

Automated systems apply labels with nutritional information,barcodes, and "best before" dates.

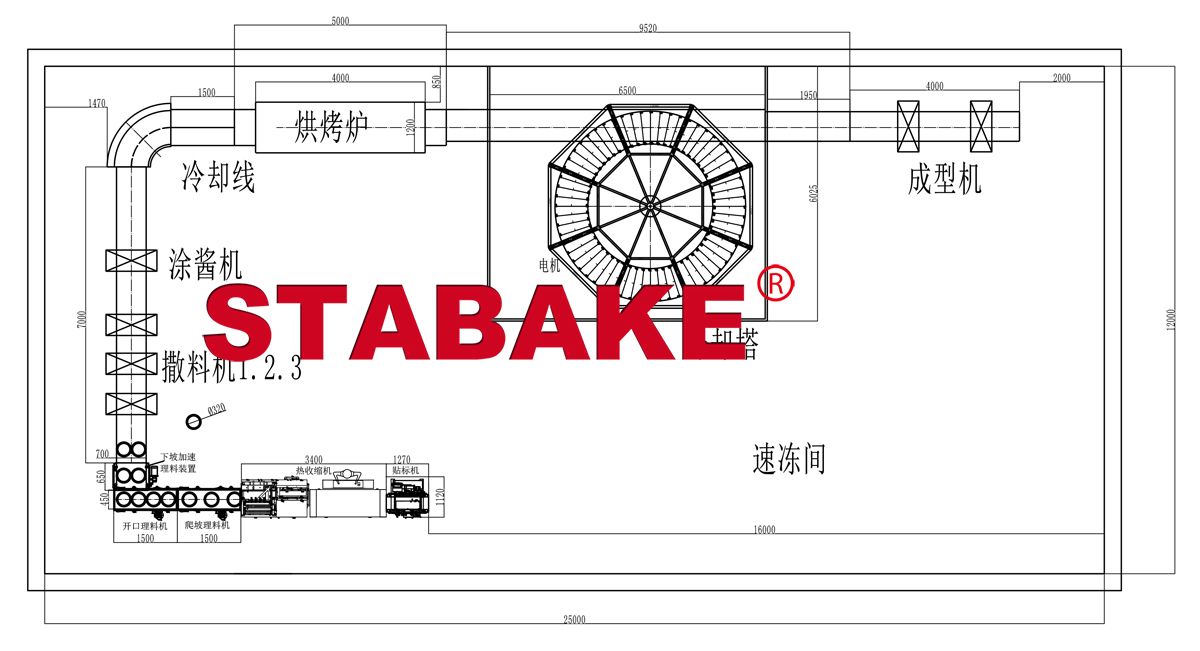

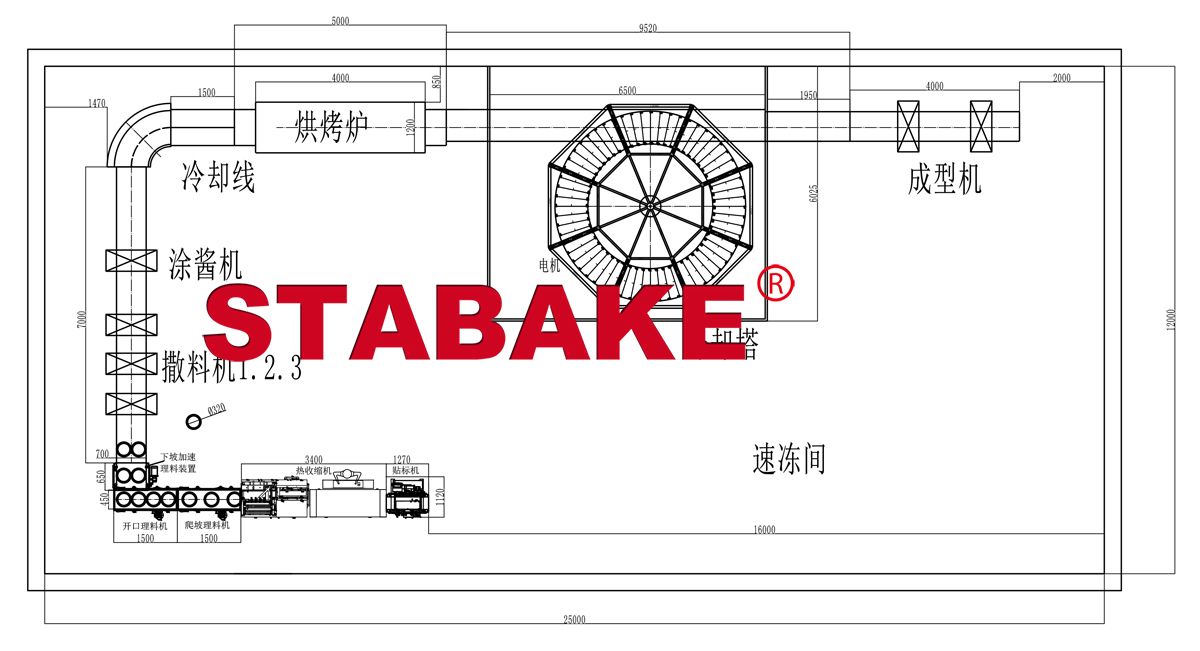

Pizza processing line Planning Proposal and Equipment:

The Pizza Production Details:

Pizza Yeasting

Pizza tunnel baking oven

Pizza

Pizza Packaging Labeling

How it Work

We are Processional in dough flour food like pizza cookies cake processing solution, the capacity can be customized as demand.

Please let us know which products you want make? we will provide the professional proposal solution. welcome to contact us