Full Automatic Continuous Potato Chips Frying Machine

Description:

The automatic frying machine adopts an oil-water mixed filter residue structure or a full-oil longitudinal scraping system, with variable frequency speed regulation, large frying output, and improved productivity. The frying machine is made of stainless steel and has an automatic manual lifting system, a unique product conveying system, a slag discharge system, and a heating system. , oil circulation system, smoke exhaust system, and electronic control system. It is suitable for users whose frying time is between 15 seconds and 15 minutes. Frying equipment with heating methods suitable for users can be made according to the energy requirements of the equipment. This machine is suitable for use by large, medium and small enterprises. Features of this machine: It can fully save frying oil for customers. The oil-water mixing system can minimize the acid value, peroxide value and carbonization process of the frying oil. Scope of application: meat, seafood, vegetables products, nuts, snack and pasta foods etc.

1. Equipment structure

(1) Basic structure: automatic temperature control system, automatic lifting system, automatic filtering and scraping system

(2) Mesh belt conveyor system: variable frequency speed regulation, capable of quantitative conveying and timing conveying

(3) Heating system: electric heating tube heating, thermal oil heating, coal heating, natural gas heating, liquefied gas heating, electromagnetic induction heating, infrared heating

(4) Automatic filtration system: dynamic oil circulation system (Oil pump, oil tank,deoiler)

(5) Smoke exhaust system

Automatic frying machine

Automatic lifting system

2. Equipment Feature

Advanced oil-water integration technology overcomes the shortcomings of conventional frying machines. Automatic filtration can keep the frying oil clean and make the fried products consistent. It not only improves product quality, extends product life, also brings safety to the product. brings higher added value.

Advanced mechanical configuration and control can always maintain good working conditions, which not only increases output but also makes product quality stable and uniform in color, aroma and taste.

The automatic filtration of this machine can greatly extend time of the frying oil. No need Frequent change oil . The oil consumed just equivalent to the oil absorbed by the product during the frying process of the product. There is no doubt about the fuel-saving efficiency.

The advanced and efficient heating system avoids energy waste to the greatest extent and saves a lot of energy expenditure.

The realization of continuous operation of this machine improves unit work efficiency, effectively reduces unit costs, and is also extremely helpful for labor expenditure and management expenditure.

Using this equipment can greatly improve product quality, reduce various costs incurred during the production process, and make your products more competitive in the market.

Specification

Model | Heat mode | Dimension and oil tank size |

FRL-3500 | Electric heating, Power 48kw electric or gas/LPG/diesel heating | Because of the different frying technics, oil tank size and power should be adjusted according to moisture content and frying time of the product. |

FRL-4500 | Electric heating, Power 90kw electric or gas/LPG/diesel heating |

FRL-5500 | Electric heating, Power 120kw electric or gas/LPG/diesel heating |

FRL-6500 | Electric heating, Power 168kw electric or gas/LPG/diesel heating |

FRL-8500 | Electric heating, Power 198kw electric or gas/LPG/diesel heating |

FRL-11000 | Electric heating, Power 240kw electric or gas/LPG/diesel heating |

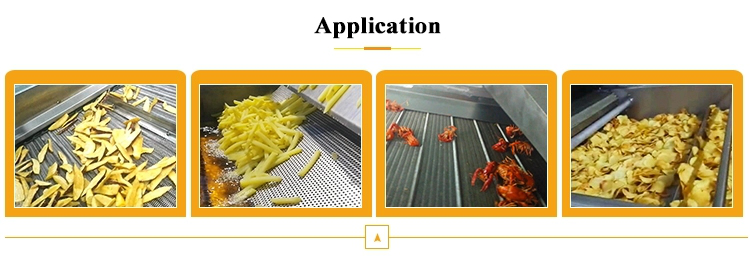

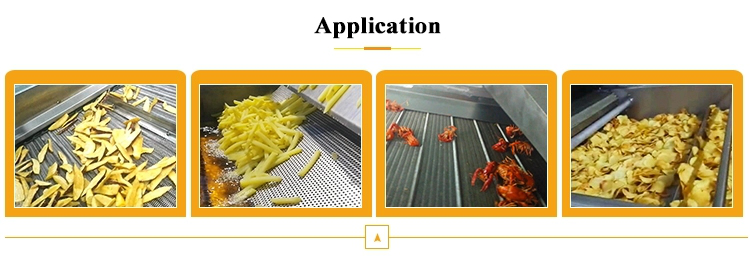

Application Scope:

Applicable products include: broad beans, green beans, peanuts and other nuts; snack foods such as crispy rice noodles and potato chips, plaintain chips, french fries; noodle products such as glutinous rice sticks, cat ears, Shaqima, and twists; meat products such as meat cubes and chicken legs, chicken drumstick, chicken cutlet; croaker, Hairtail fish and other seafood; dried tofu, tofu soak and other soy products, etc.

The fryer machine is widely used in food snack frying process factory, restaurant, hotel, etc.