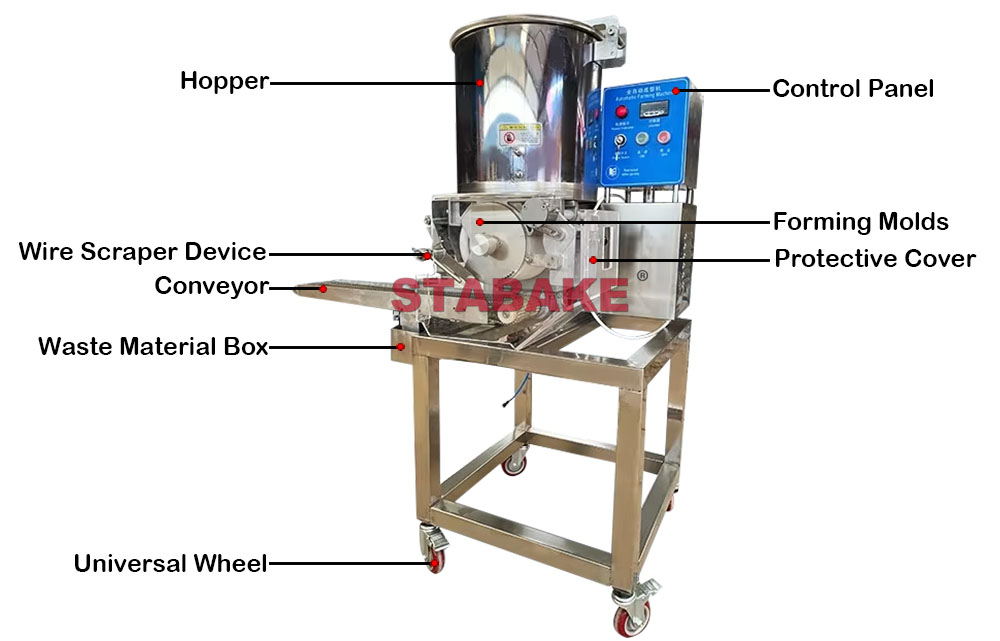

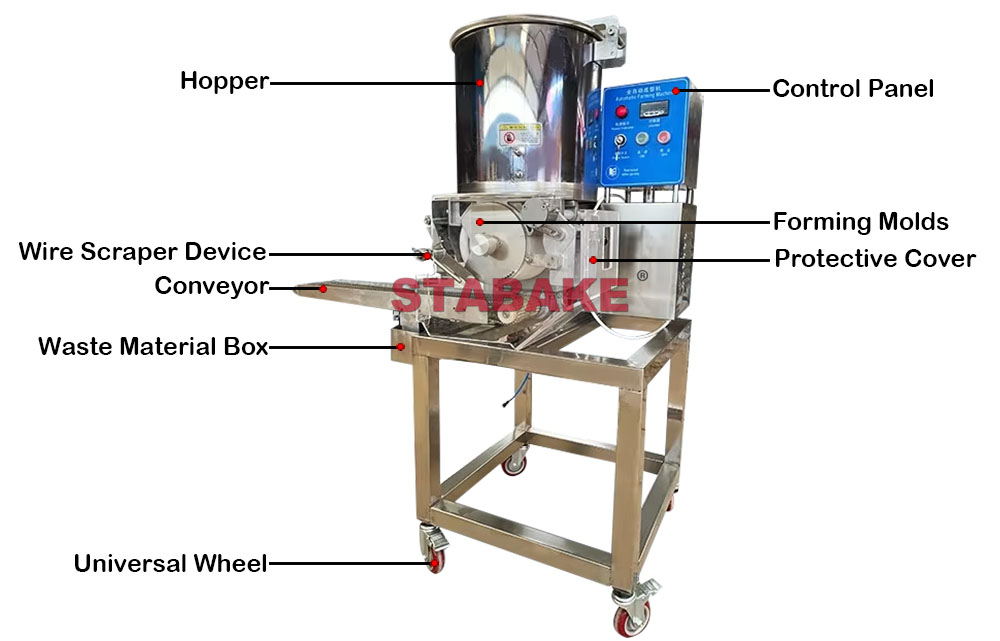

| Hamburger Patty Forming Machine Descriptions |

The hamburger patty forming machine (also known as a patty forming machine) is an industrial-grade commercial food processing machine primarily used for the automated production of hamburger patties, chicken nuggets, fish patties, vegetable patties, and other products. |

| Features: |

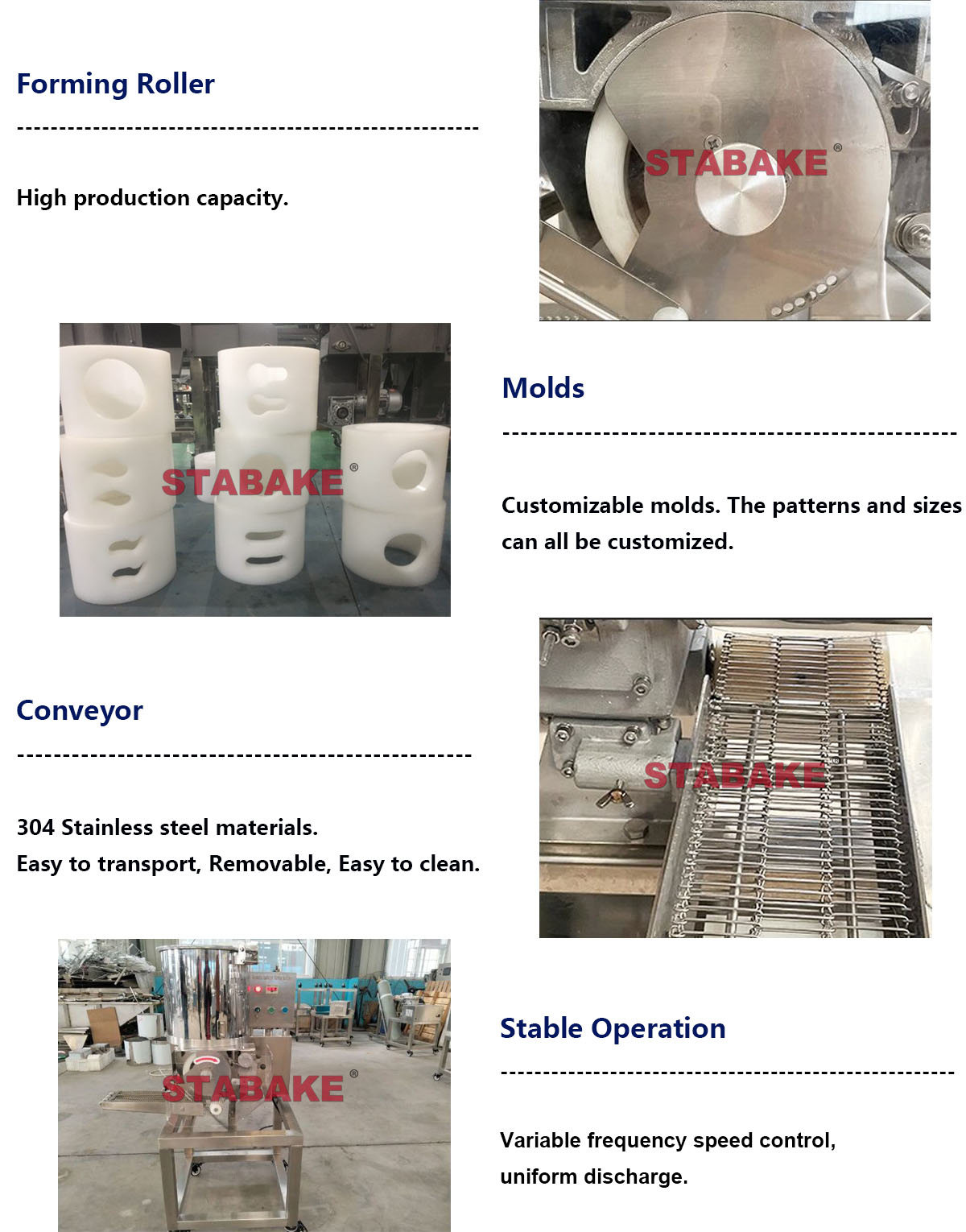

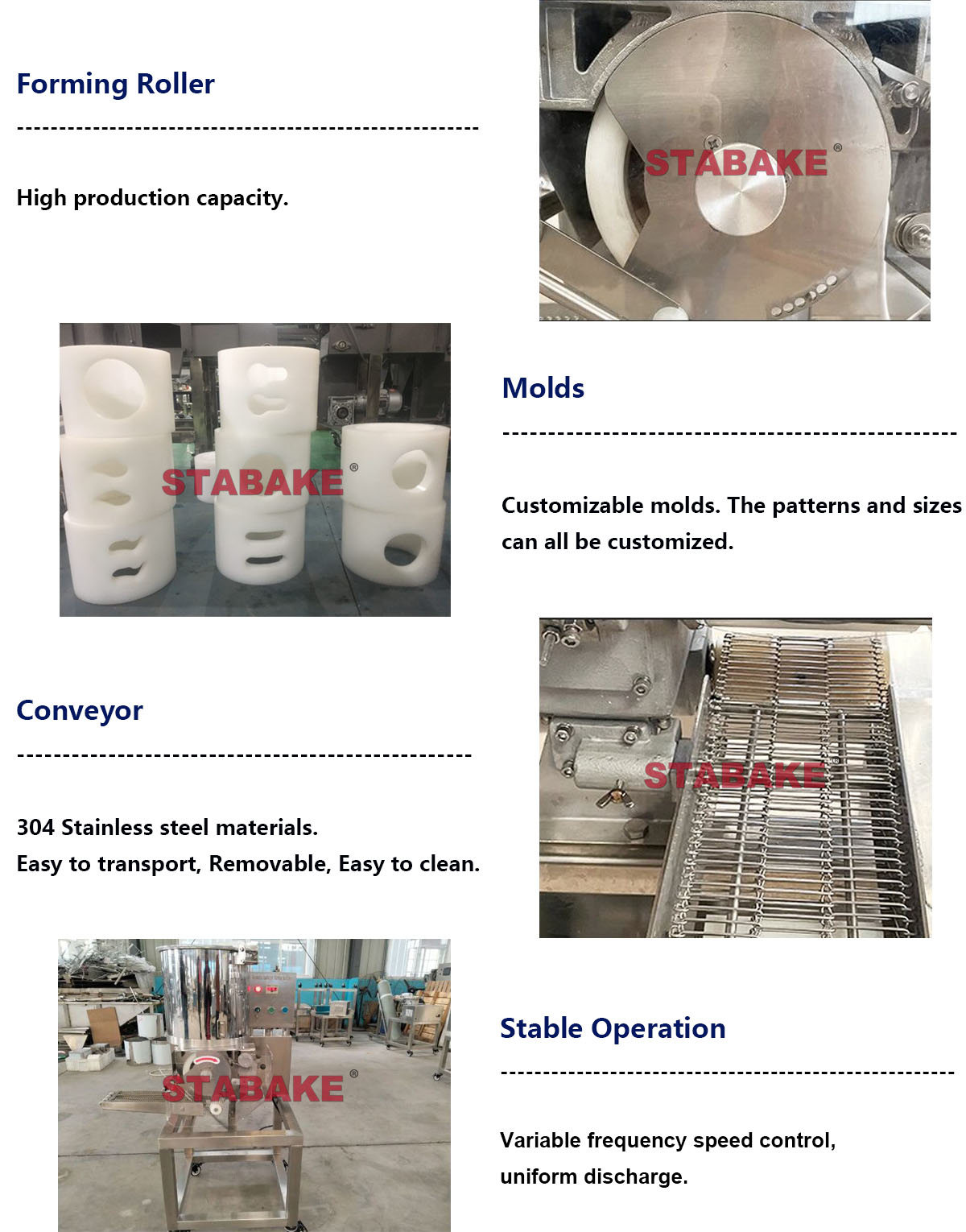

| 1. Automated Production Process • Integrated automatic filling, forming, pasting, and conveying functions. • A variety of shapes (round, square, heart-shaped) and products (patties, meatballs, potato patties, etc.) can be produced by changing molds. |

|

|

|

| 2. High Production Capacity • Output ranges from 2100–2600 pieces/hour (varies depending on the product). |

3. Material and Hygiene Standards • The main body is constructed of food-grade 304 stainless steel, meeting hygiene standards. |

4. Flexible Adaptability • Adjustable thickness (7–21 mm) to meet different product weight requirements. • Compatible with a variety of ingredients: beef, chicken, fish, vegetables, breadcrumbs, cheese, and other mixed fillings. • Specialized scrapers are available (strip scrapers for red meat, wire scrapers for white meat/fish). |

5. Production Line Integration Capabilities • Can be integrated with battering machines, fryers, and conveying equipment to form a continuous production line, supporting both baking and battering and deep-frying processing modes. |

| Technical Parameters: |

| Model | HCX-100III |

| Power | 0.55kw |

| Bin Volume | 30L |

| Capacity | 50-100kg/h(35pcs/min) |

| Patty Diameter | Max 11cm |

| Patty Thickness | 7-21mm |

| Diameter | 860*600*1400mm |

| Weight | 100kg |

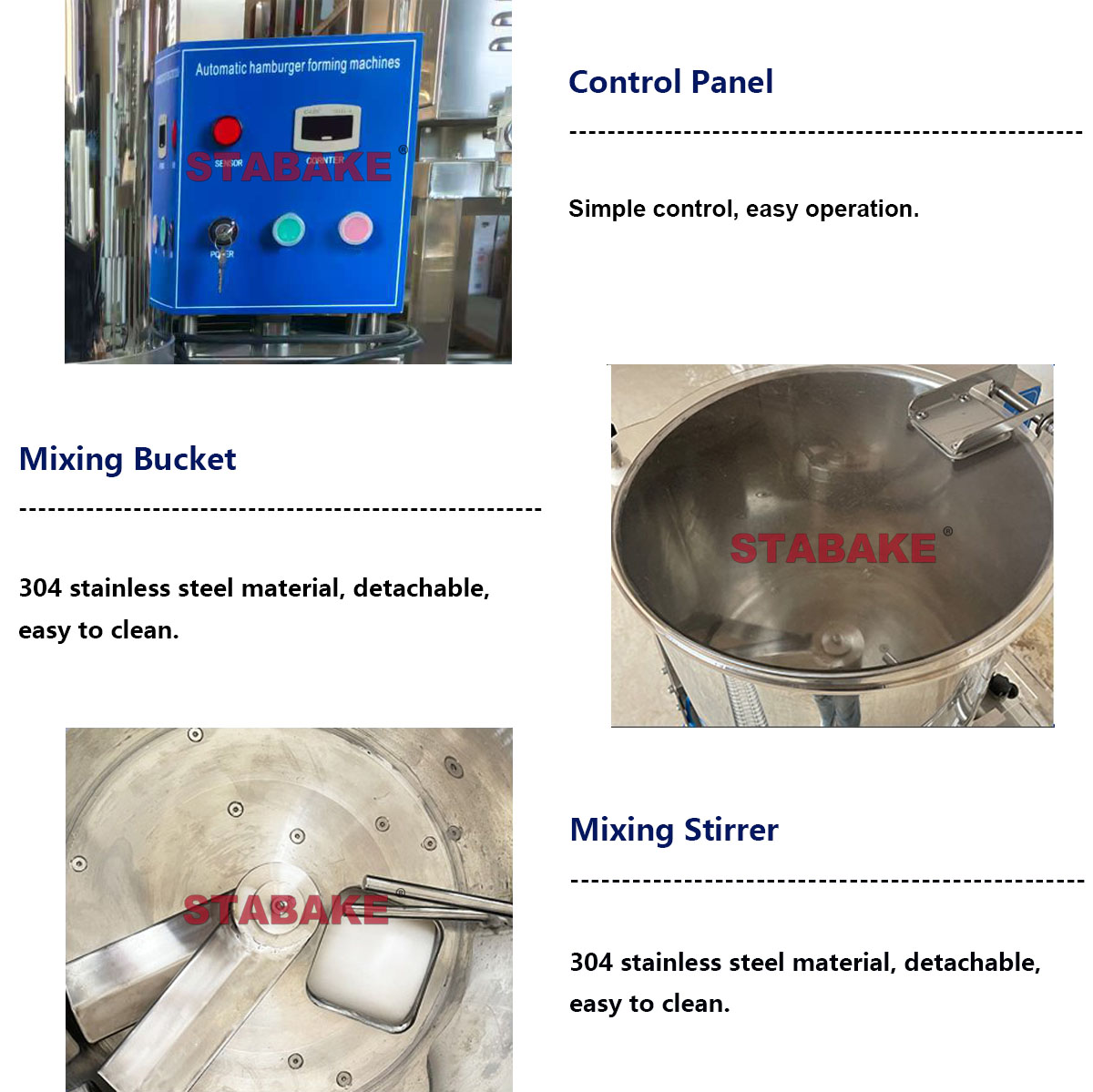

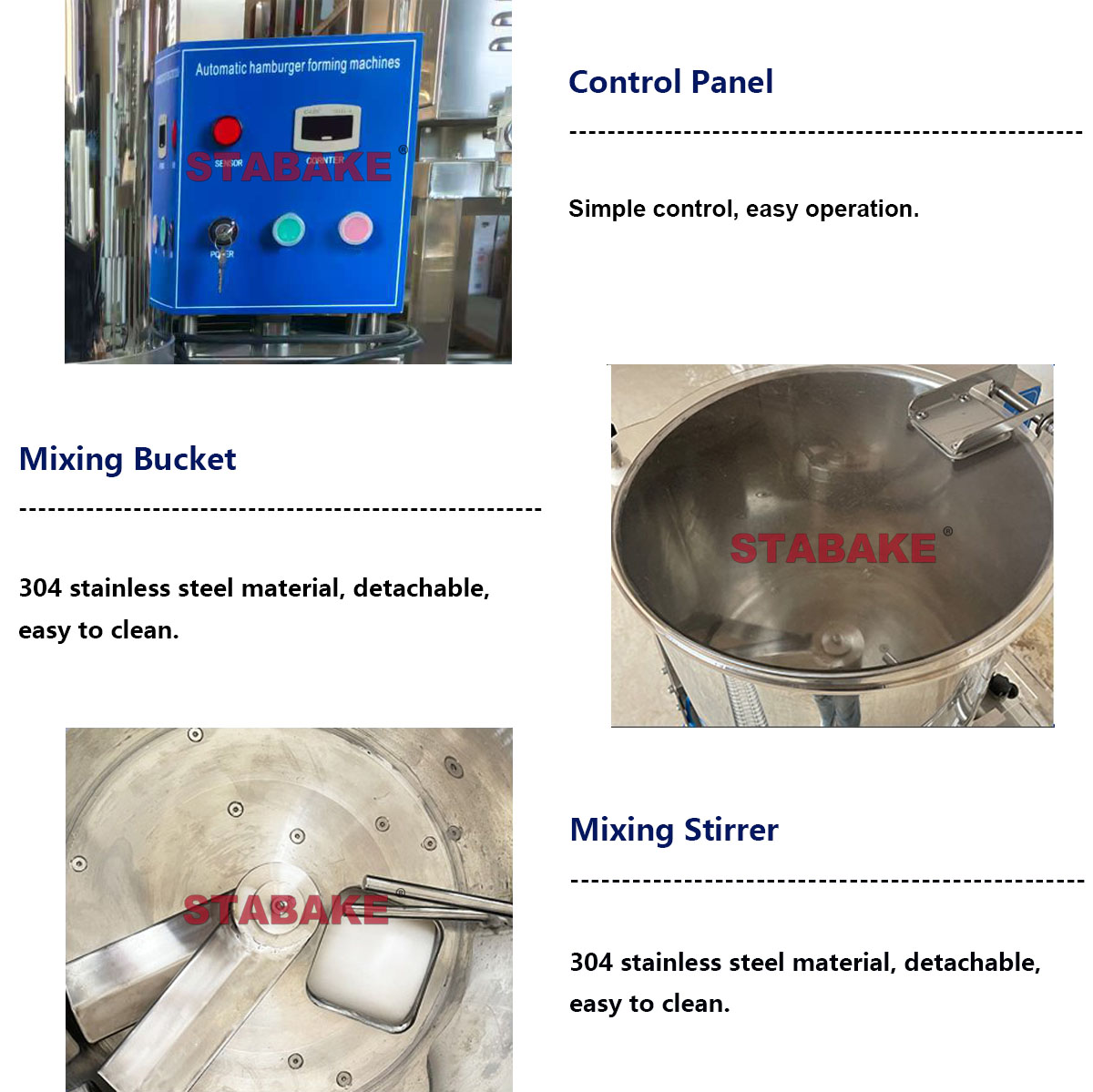

| Machine Details |

|

|

|

Machine Display

|

|  |