As the health demand drive, Consumers' attention to healthy diet continues to increase. The low calorie and high dietary fiber characteristics of konjac food make it an ideal choice for people who want to lose weight and control sugar, and demand continues to grow. In 2022, the global konjac market size has reached 590 million US dollars, and maintained a stable annual growth rate of about 11%.

About Konjac Processing and Solution

About the konjac processing, StaBake offers you equipment and consulting service includes peeling, cleaning, slicing, drying, grinding, purified or equipment for konjac food making machines. There are usually 3-4 stages in the konjac processing.

1) First Stage: Raw konjac can be dried into konjac chips.

2) Second Stage: Konjac chips can be ground into konjac flour (remove the starch)

3) Third Stage: Konjac flour can be purified into the glucomannan powder (also called Gum) by ethanol

4) Fourth Stage: Konjac flour can be made into the food of traditional shirataki rice, konjac silk, konjac tofu, Konjac vegetarian tripe, and diversified products such as konjac snacks, konjac drinks, and konjac seasonings and so on.

|  |  |

First stage: Dried Konjac Chips | Second stage: Konjac Flour | Third Stage: Glucomannan powder |

According to processing requirement and situation, our engineers will provide professional solution and consulting service on production line planning, such as factory layout design, machine size customize in order to helping you build the konjac processing line and start up your business successfully.

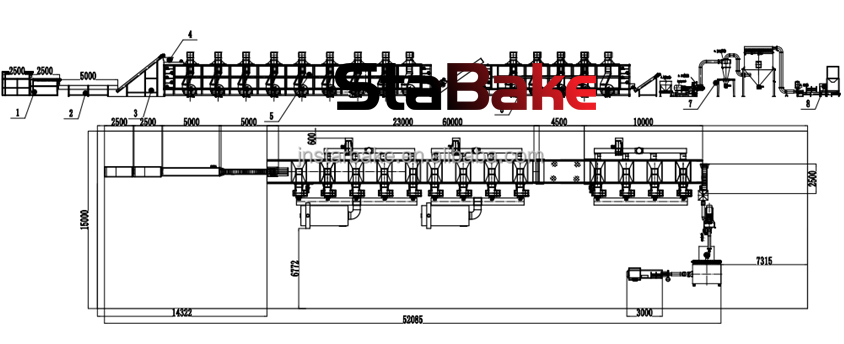

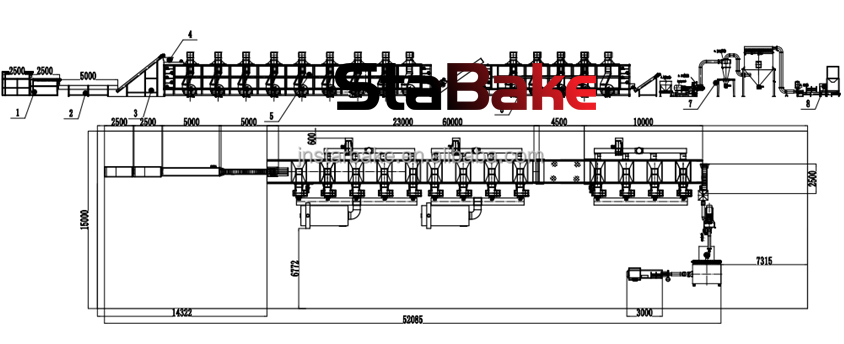

In the solution below is the complete konjac flour processing line. The automatic working from konjac peeling to last grinding and evening packing, and these machines can be customized in size according to customers’ production capacity needs. Please contact us or fill the form to get more specification and quotation.

Konjac Chips Drying And Flour Grinding Processing Line

How it work:

About Konjac Drying Processing Solution

This konjac drying processing solution for processing of fresh konjac into dried konjac chips or konjac flour, good processing effect. The capacity can be customized as you need: 100kg/h, 200kg/h, 300kg/h, 500kg/h, 1000kg/h etc.

Konjac Powder Production Planning Proposal And Equipment Details

Flow chart: Soaking hopper- Continuous peeling machine- Pick line – Slicing Machine – Drying machine- Grinding - Package machine

| Specification of Konjac Flour Processing Line (1 ton/h capacity) |

| No | Equipment | Qty | Parameter |

| 1 | Lifting Conveyor | 1 | 3000*800*2500mm |

| 2 | Washing and peeling machine | 1 | 2600*850*900mm |

| 3 | Bubble washing machine | 1 | 4000*1000*1800mm |

| 4 | Roller Picking line | 1 | 6000*1000*750mm |

| 5 | Lifting Conveyor | 1 | 5000*800*3000mm |

| 6 | Cutting machine | 1 | 1800*1200*1400mm |

| 7 | First Stage Hot air Drying machine chamber | 1 | 15000*8600*3600mm |

| 8 | Second Stage Hot air Drying machine chamber | 1 | 20000*8600*3600mm |

| 9 | Automatic flour Grinder system with dust remover | 1 | 6000*2600*3000mm |

| 10 | Powder vibrating sieve | 2 | 1300*1300*1000mm |

| 11 | Powder Automatic weighing packing machine | 1 | 3000 *720 *1900mm |

Machine specification

Frist stage: Konjac Chips Process: Peeling- Washing- Slicing- Drying

1. Konjac Brush roller peeling machine

The brush peeling machine with screw for continuous working, please click the following photo to check the peeling machine specification:

2. Konjac Bubble washing machine

Please click the following photo to check the washing machine specification:

3. Konjac Slicing Machine

The konjac slicing machine is STABAKE special machine, customized to cutting konjac into slices. The machine will be used equipped with the konjac drying machine.

4. Konjac Chips Drying Machine

STABAKE konjac drying equipment is a belt type muti-layer reverse dryer. The main parts are made of SUS304 stainless steel. The stainless steel mesh belt runs smoothly, it’s easy to maintain and has a long service life. The whole machine running speed and drying temperature can be set according to production needs. High-level of automation, saving labor and improving production efficiency. please click the following photo to check the peeling machine specification:

Second Stage: Konjac Flour Process: Crude Crushing – Fine Grinding – Fine Milling

5. Konjac Chips Crude and Fine Crushing Machine

6. Konjac Flour Milling Machine

Third Stage: Glucomannan Powder Processing

Fourth Stage: Konjac Vegetarian food making, such as Tofu, Shirataki rice, wet noodle, snacks, tripe,jelly and so on