Air Bubble vegetable washing machine

Description of vegetable washing machine

The QX Series Air bubble cleaning machine is developed according to vegetable processing industry demand. which helps to solve the washing problems of fruits, vegetables (fresh vegetables, pickled vegetables, fungi, etc.), aquatic products, medicinal materials, etc.

The machine adopts the cleaning principle of high pressure air bubble, with bubble generator in the water tank , the air bubble can rub material and make them roll, imitating manual washing.

The air bubble washing machine could be used for all kinds fruits and vegetables washing and could be configured in many types of fruit vegetable processing line.

1) Vegetable drying processing line : Peeling Machine-Cutting Machine- Bubble washing machine- Air Blower Drying Machine- Dehydrator Machine - Grinding Machine -Packing Machine

Feature

With a partition board. effectively separates the cleaning materials from the washed sediment, reduces the turbidity of the water, greatly improves the recycling rate of cleaning water, saves 80% of the cleaning water

With a circulating water pump and filtered water tank to realize the recycling of cleaning water.

With a spray device on the end lifting section secondary washing with clean water.

Conveyor speed adjustable and Meash belt runs stably. The materials is fixed travel with the movement of the mesh belt, avoid damage to the materials.

SUS 304 stainless steel, meet food grade standard.

Famous Schneider brand electric control appliances.

Ozone Generator of UV/O3 water treatment system to disinfect and sterilize are optional.

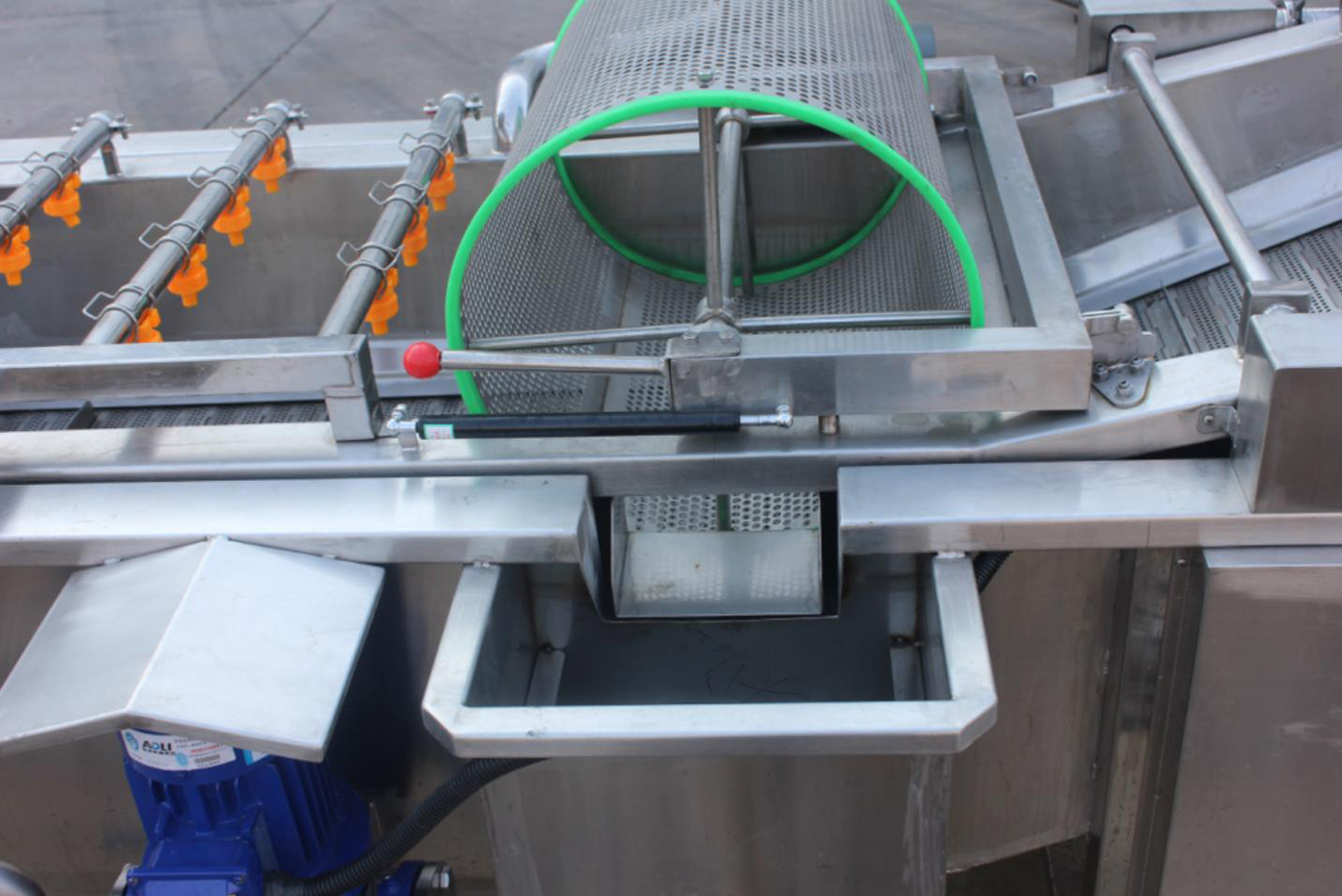

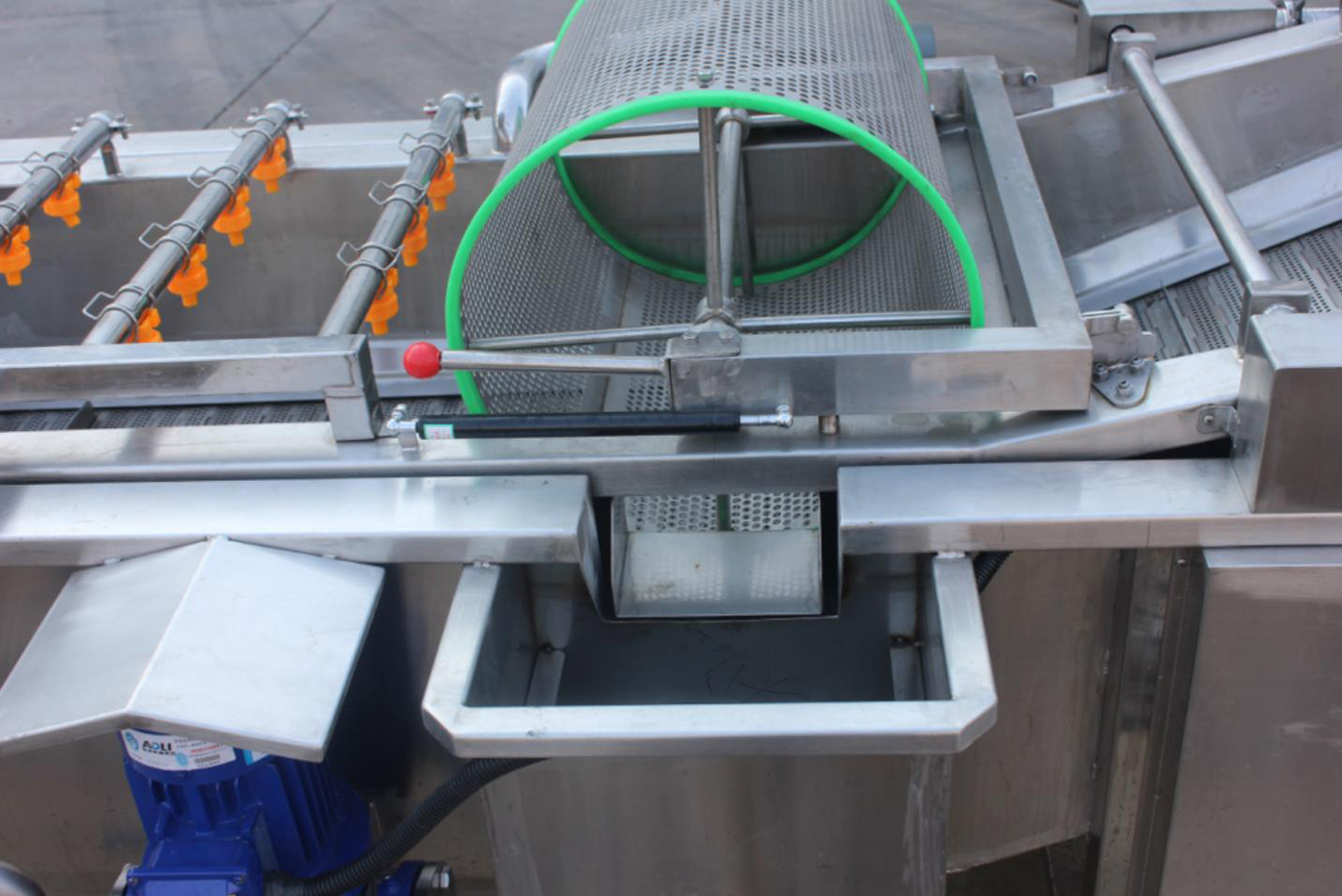

Three kinds of purify device are option (filtered tank, brush roller or arc filter).

Filtered tank

Brush roller

Arc filter

Working Principle

The material enters the water tank and is fully dispersed, tumbling, cleaned and transported under the action of high-pressure water flow and strong bubbles. The sediment washed off from the vegetable surface will sinks into the bottom isolation bin, and will not be flipped back and cause re-contamination. The Debris and bugs floating in the water are collected through the mesh collecting mechanism, and the filaments, hair, etc. are cleaned out through the brush roller. After the washed materials are discharged from the water, they are spray-cleaned and sent to the next process.

Technical Parameter:

Model | Belt Width | Power | Capacity | Dimension | Weight |

QX250 | 250mm | 3.75kw | 500kg/h | 2500*1000*1300mm | 180kg |

QX400 | 400mm | 4.1kw | 800kg/h | 4000*1200*1300mm | 400kg |

QX500 | 500mm | 5.1kw | 1500kg/h | 5000*1200*1300mm | 500kg |

QX600 | 600mm | 5.5kw | 2000kg/h | 6000*1200*1300mm | 600kg |

Application

The air bubble washing machine Suitable for all kinds of fresh fruits and vegetables, salted vegetables, fungi, seafood and medicinal materials.

1. Cleaning operations for a variety of fruits and vegetables: peas, cauliflower, rape, cucumber, spinach, tomatoes, strawberries, apples, etc.

2. Cleaning operations for various agricultural products: wolfberry, jujube, chestnut, peanut, hawthorn, etc.

3. Cleaning operations for a variety of seafood: fish, shrimp, starfish, crabs, etc.

Vegetable Washing

Peas Processing

Fruit Cleaning

Jujube Cleaning

Seafood Cleaning

Vegetable Washing Processing Machine

Vegetable Cleaning Processing Machine

Remark:

we can design the machine based on your requirement. And Voltage can be customized.

In order to give you proper design,Please kindly tell us your exact requirement below:

1. What kind vegetables or fruits do you want to wash, whole or cutted?

2. What is your expected production capacity, kgs/h and kgs/day?

3. What is your next process after washing?