Complete Indonesia 1000 kg/h Automatic konjac Drying Machine konjac processing line konjac chips dryer line

Automatic 500~5000kg Continuous Conveyor belt Drying Machine/Dryer system

Description:

This equipment is a belt type multi-layer dryer

1.The main parts are made of high quality carbon steel or SUS. The stainless

2.steel mesh belt is made of SUS304, it runs smoothly, easy to maintain and has a long service life.

3.The whole machine running speed and drying temperature can according to production needs set.

4.It’s has a high degree of automation, saving much labor and improving production efficiency,large capacity with best drying effect.

5.The heating method can be :natural gas,LPG,diesel oil and steam or heat pump

6.Application :Konjac,parsley,ginger,garlic chips,onion,chili,hemp ,vegetable and other raw material with high moisture

7.we can provide the complete solutions for you according to your requirements.

Drying principle:

The working principle is that the air heated by the heat source in the hot air stove ,is blown by circulation fans into the inside of the drying main body, then the moisture of the stuff is evaporated under the heat. the inner moist air is discharged to the outside of the device with the exhaust pipe. The machine can continuously feed and make the material run smoothly. During the material conveying process,the mesh belt can realize the turnover of the material and reach the homogeneity of the heated wind on all surfaces. It can connect with other equipment to achieve continuous operation.

Product parameter:

| NO. | Description | Specification | QTY/sets | Price/set

FOB Qingdao | Options |

| 1 | Feeding conveyor | 4200*2200*3500mm | 1 | $4500 | / |

| 2 | Continuous dryer | 10000*3200*3700mm | 1 | $38000~115000 | UL motors 8sets, plus |

| 3 | Hot air stove | 4000*2000*1800mm | 1 | $12000 | / |

| 4 | Gas burner | RIELLO brand Power:400000kcal/h | 1 | $2000 | If Siemens touch screen controller is needed, add 3000us |

| 5 | Electricity Distribution Controller | 4000*800*1800mm Power: 0.55kw | 1 | $1500 | /UL motors 1set,500usd |

| 6 | Discharge conveyor | 4000*800*1800mm Power: 0.55kw | 1 | $2500 | /UL motors 1set,500usd |

| 7 | Total weight | 13000kg |

|

|

|

| 8 | Total price (FOB Qingdao) Container | 2*40HQ | 7 |

$60500~2000000 USD | $65000USD |

Customized different capacity dryer

We can customize different capacity dryers and different heating methods according to the characteristics of drying materials and the different capacity of the clients' requirements.Type:8m-3layers.8m-5layers.10m-5layers.15m-3layers.20m-5layers.30m- 5layers. Capacity: 300kg/h~3000kg/h ,depending on the moistuure and drying temperature.

Heating method: Electricty or gas or steam or heat pump.

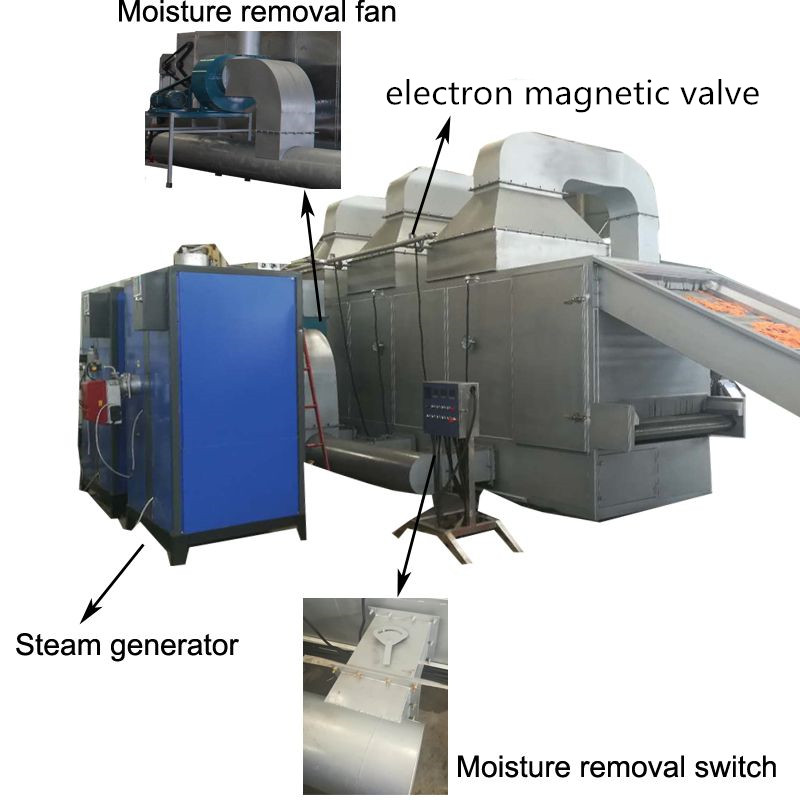

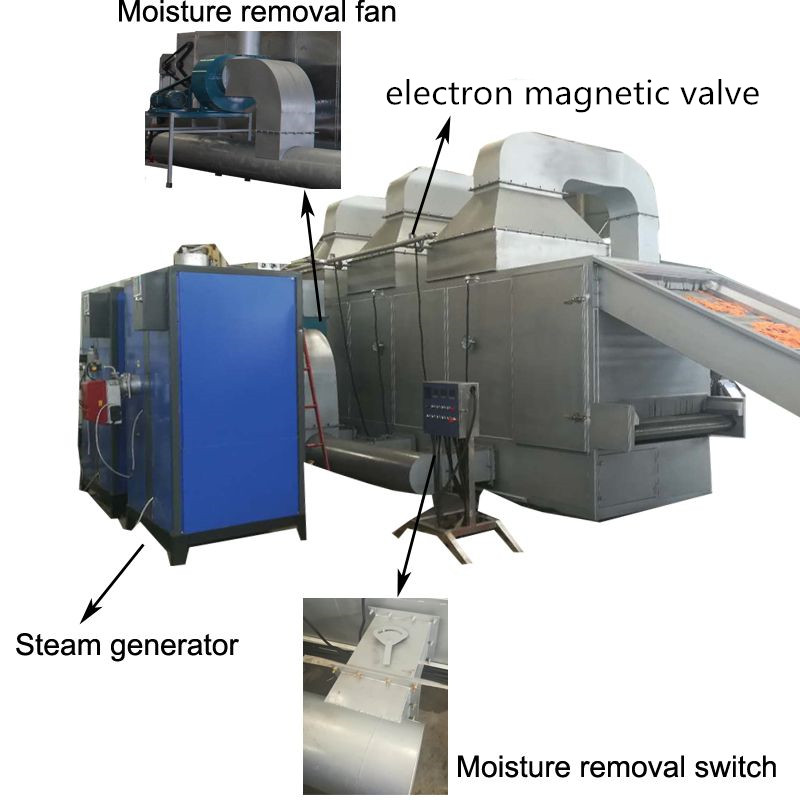

Main components

1. Circulation fan: The circulating fan can blow the hot air generated by the hot stove into the dryer chamber.

2. Air volume controller: When the air temperature in the hot blast stove is too high, the valve is properly opened, which can replenish fresh air and regulate the temperature inside the dryer.(only steam-heated dryer needed)

3. Dehumidifier fan: It can discharge the damp air.

4. Moisture control valve: When the air temperature rises, the valve can be enlarged a little. It can accelerate the removing of moisture.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Jinan Starbake Food Machinery Co., Ltd is located in Jinan City, Shandong Province. Our products mainly sold to the United States, Singapore, Russia, kazakhstan, United Kingdom and so on.The company has 12000 square meters of factory buildings and 1500 square meters of office space. The company have 60 employees,15 technical personnel,41 workshop staff and 10 welfare officers among them to provide the best service and solutions for our clients.

Our company's main products include complete solutions,automatic large-scale hot air drying machine,heat pump drying machine and grinding machine line, potato chips frying (frozen) processing equipment, fruit & vegetable washing machine, pasteurizer ,and cooking equipment, etc.

Welcome to Starbake machinery!

Sincerely hope we can cooperate with you!

1.Are you a manufacturer or a trading company?

We are a professional manufacturer of food machinery.Especially for vegetable and fruit drying and snack food

processing production line.

2.What's the price of your machines?

You can inquiry to us directly and negotiate furtherly.

3.What is your payment terms?

T/Tor L/C; by T/T 40% as down payment, 60% by T/T before delivery, L/C at sight.

4.Can we provide the formula to you?

We can provide basic formula .And help customer to produce good quality food .