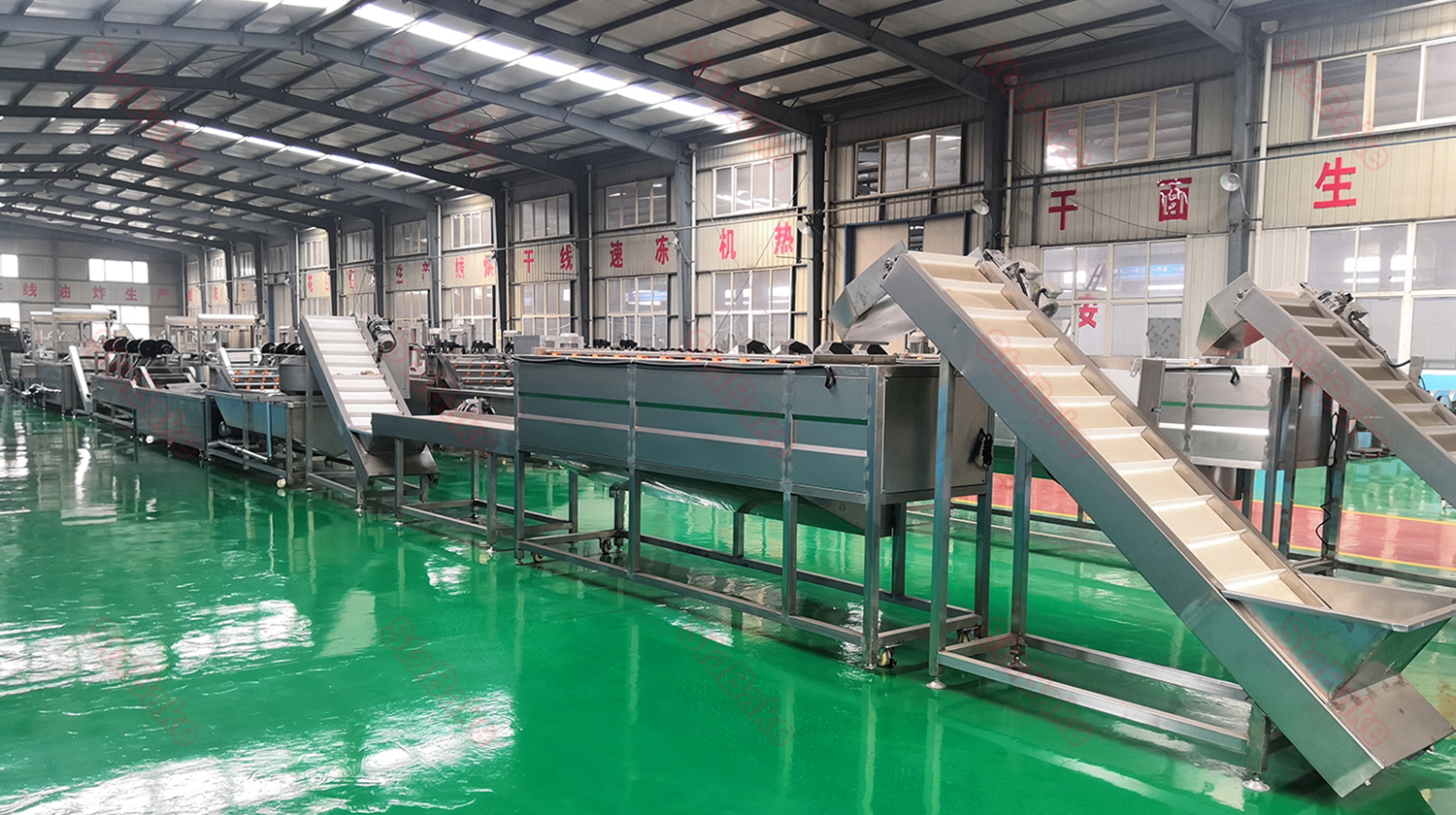

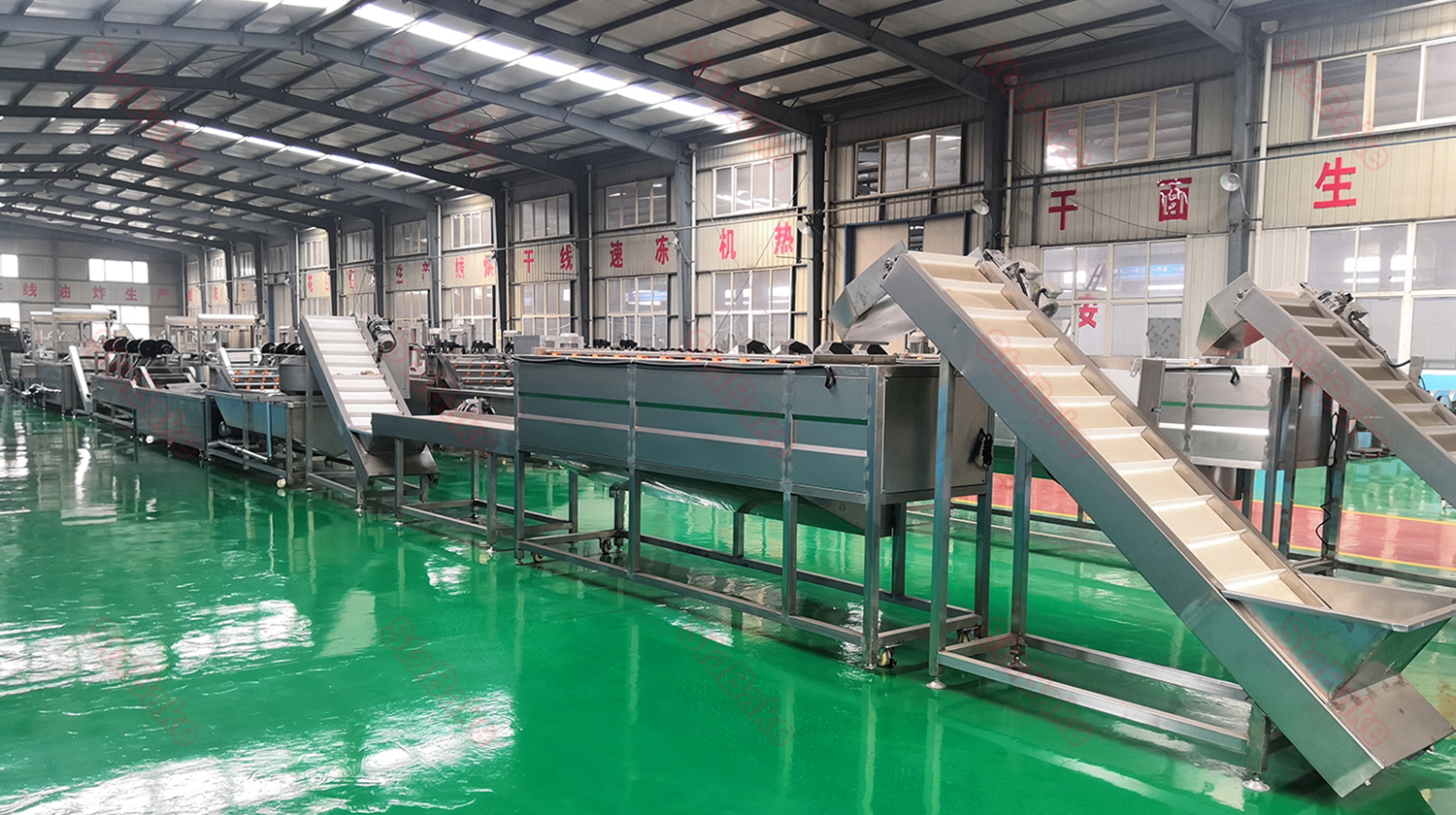

High Productivity Complete Line Potato Chips Making Machine

Instruction:

Fried Potato chips is one kind of snacks processed from fresh potato after washing, peeling, slicing ,frying and flavoring. It remains the special delicious flavor of roasted potato on one respect and has the characters of rich nutrition, delicious. it is very popular among the customers all over the world.

This potato chips frying production line is the best choice for making potato chips with low investment and power consumption. This whole line is made up of potato washing peeling machine, potato cutting machine, blanching machine, dehydrating machine, frying machine, deoiling machine, flavor mixing machine and nitrogen filling packing machine.

we can provide automatic or Semi automatic processing plant which according to different capacity and requirement for different customers. Such as 50kg/h, to 100kg/h, 300kg/h, 500kg/h, 1000kg/h, 2000kg/h capacity potato chips production line.

Specification:

Name | Potato Chips Production Line |

Capacity | It is 4:1 for fresh potato and finished potato chips.

And our output capacity for potato chips is 100,150,200,300kg/h. |

Fresh potato requirement | 1.Diameter is about 40—60 mm, regular shape;

2. Inside is white, small bud ;

3. Drying material content is about 22—25%.

4. deoxidize sugar content ≤0.2%: before using the potatoes, it is needed to put storage potatoes in another room whose temperature is about 12-18 °C and last for 1 week |

Potato chips specific | it is about1.5- 2mm; size and thickness is in uniform, surface is smooth |

Power Require | 380/220V 50HZ, 3 PHASE |

Application:

The potato chips processing line is suitable for making different products such as potato chips, plantain chips, taro chips, cassava chips, sweet potato chips and so on.

potato chips

plantain chips

taro chips

cassava chips

sweet potato chips

Fried vegetable

Production Planning Proposal And Equipment Details

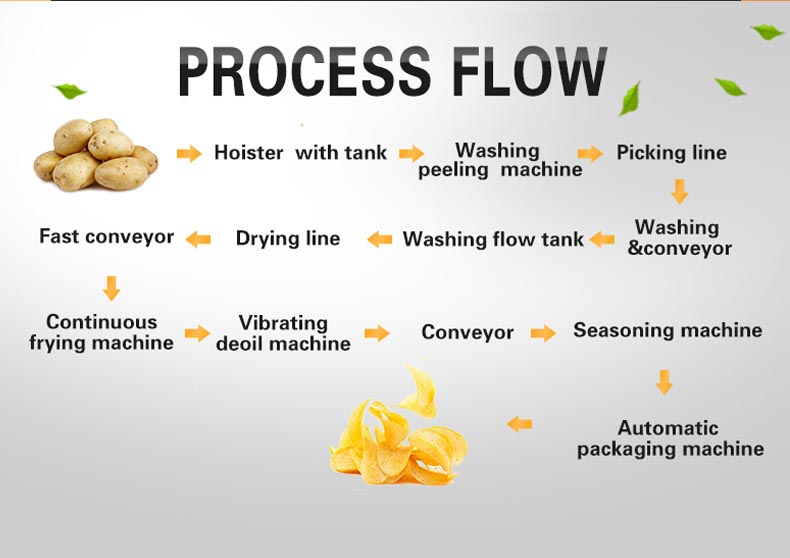

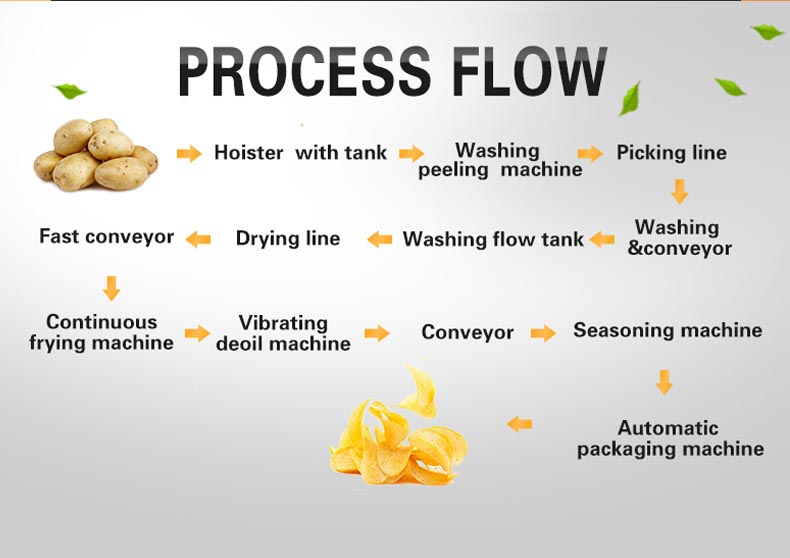

Flow chart: Soaking Pool with Feeding Elevator→Brush Washing Peeling→Pick Line→Conveyor→Cutting Machine→Impurity Removing →Bubble Rinsing→Continuous Blanching→Vibrating De-Watering→Parallel Air Dry Line→Elevator Conveyor→Continuous Frying→Vibrating De-Oiling→Parallel Air Cooling Line→Elevator Conveyor→Seasoning→Automatic Packing

Flow chart: Soaking Pool with Feeding Elevator→Brush Washing Peeling→Pick Line→Conveyor→Cutting Machine→Impurity Removing →Bubble Rinsing→Continuous Blanching→Vibrating De-Watering→Parallel Air Dry Line→Elevator Conveyor→Continuous Frying→Vibrating De-Oiling→Parallel Air Cooling Line→Elevator Conveyor→Seasoning→Automatic Packing

No. | Equipment | Function |

1 | Feeding Conveyor | For elevating and conveying potatoes into the next washing peeling machine |

2 | Brush Washing and Peeling Machine | Thoroughly washing and peeling the potatoes Brush washing peeling machine use of brush-type cleaning peeling can be completed cleaning and peeling work at the same time. High efficiency, low loss. |

3 | Picking Line | For manually disposing the uncleaned places and selecting the defective potatoes |

4 | Potato cutting machine | Cutting potato slivers or potato chips (slivers' size and chips' thickness can be adjusted through adjusting blades. ) |

5 | Pre-rinsing bucket | Pre Rinsing the slivers and chips then convey them to impurity machine |

6 | Impurity Machine | Remove the short and offcut pieces(only used for french fries making line) |

7 | Rinsing Machine | Through high pressure water flow and water bubbles to wash off the starch of potato slivers or potato chips |

8 | Blanching Machine | Through 60-95 degree hot water blanching to protect potato sliver or chips from oxidation, keep its original color and quality. color protection. |

9 | Vibrating Dewatering Machine | Shake to remove surface water and spread the potato slivers or chips for next step air drying. |

10 | Air Drying Machine | Through high pressure fan blowing for pre-cooling and removing the excess water in a short time, prevent the fried oil jumped phenomenon and greatly shorten the frying time and improve the taste of potato chips. Improve production efficiency and reduce production costs. |

11 | Automatic Frying Machine | For frying the potato slivers or chips. Frying temperature 0-220℃adjustable; Frying time frequency adjustable. Electric heating or gas heating, automatic temperature control with automatic filtration system, Mesh with frequency control, constant temperature frying, can make the product fry at a temperature from start to finish, to ensure uniform products, thus ensuring the quality and taste of potato chips. Scraping part can fry the scraps produced during the frying process to ensure that the dregs do not pollute the fried products, and the lifting part can enhance the equipment and mesh belt during equipment cleaning for easy cleaning. |

12 | Vibrating Deoiling Machine | De-oiling machine: Centrifugal de-oiling machine or air-cooled de-oiling machine, will just fried potato chips (strips) for de-oil, to overcome the potato chips (strips) high oil content, greasy mouth defects. Improve the taste of potato chips. |

13 | Air Cooling line | Through high pressure wind blowing for pre-cooling and deoiling the potato slivers or chips |

14 | Elevator Conveyor | For lifting the finished potato sliver to Freezing machine; or convey the chips into seasoning machine |

15 | Seasoning Machine for Potato chips | Automatic seasoning machine: drum seasoning machine made of stainless steel. Potato chips (strips) are flipped evenly over the rotation of the drum, using sauces or spray to add seasonings. Uniform seasoning is not fragile. |

16 | Packing Machine | Automatically pack potato chips(strips) into bags. Automatic Feeding, Metering, Bag Filling, Date Printing, Inflatable (Exhaust), the Whole Process of the Finished Product Output. Nitrogen filling machine: When packing, filling the bag with nitrogen, which can effectively prevent chips (pieces) broken, extend the shelf life. Inflatable, packaging, a code to complete. |

Flow chart: Soaking Pool with Feeding Elevator→Brush Washing Peeling→Pick Line→Conveyor→Cutting Machine→Impurity Removing →Bubble Rinsing→Continuous Blanching→Vibrating De-Watering→Parallel Air Dry Line→Elevator Conveyor→Continuous Frying→Vibrating De-Oiling→Parallel Air Cooling Line→Elevator Conveyor→Seasoning→Automatic Packing

Flow chart: Soaking Pool with Feeding Elevator→Brush Washing Peeling→Pick Line→Conveyor→Cutting Machine→Impurity Removing →Bubble Rinsing→Continuous Blanching→Vibrating De-Watering→Parallel Air Dry Line→Elevator Conveyor→Continuous Frying→Vibrating De-Oiling→Parallel Air Cooling Line→Elevator Conveyor→Seasoning→Automatic Packing