By integrating advanced automation and freezing technology, a frozen corn processing line delivers premium-quality products that meet the growing demand for convenient, nutritious, and sustainably produced frozen foods. The corn processing line including 3 process:

First stage process: Raw Corn Pretreatment Processing

Second stage process: Ready-to-eat Fresh Sweet Corn Processing

Third stage process: Frozen corn processing

Raw Corn Pretreatment Processing Line

Processing Flow: Fresh sweet corn - Corn dehusker - topping and tailing cutting machine -Corn cob length sorting-High pressure corn silk removing-Film packing

Equipment instruction:

Corn husk peeling - This machine is designed to remove the outer husk (or husks) from the sweet corn cobs efficiently.

It operates by mechanical means, gently (stripping) the husk without damaging the cob or the kernels.

Topping & Tailing Machine - After dehusking, the topping and tailing machine trims off the unwanted top and tail

portions of the corn cob, leaving only the edible middle section. This ensures a neat and uniform appearance for

the final product.

Corn Cob Length Sorting - Next, the corn cobs are sorted according to their length. This step ensures that cobs of

similar size are grouped together, which is important for packaging and presentation purposes. Automated

conveyors and sensors are often used for this sorting process.

High Pressure Corn Silk Removing - The high-pressure corn silk removing machine utilizes high-pressure water or

air to thoroughly clean the cobs, removing any remaining silk, dirt, or other impurities. This step is crucial for

maintaining hygiene and quality in the final product.

Film Packing - Finally, the processed sweet corn cobs are ready for packaging. Film packing machines are used to

wrap the cobs individually or in groups, using a transparent or opaque film that preserves freshness and extends

shelf life. These machines can be adjusted to accommodate different package sizes and types, ensuring that the

final product meets the customer's specifications.

This fresh sweet corn processing line combines advanced machinery and technology to ensure efficient, hygienic,

and high-quality processing of sweet corn. From dehusking to packing, each step is carefully designed to

maximize product quality and minimize waste.

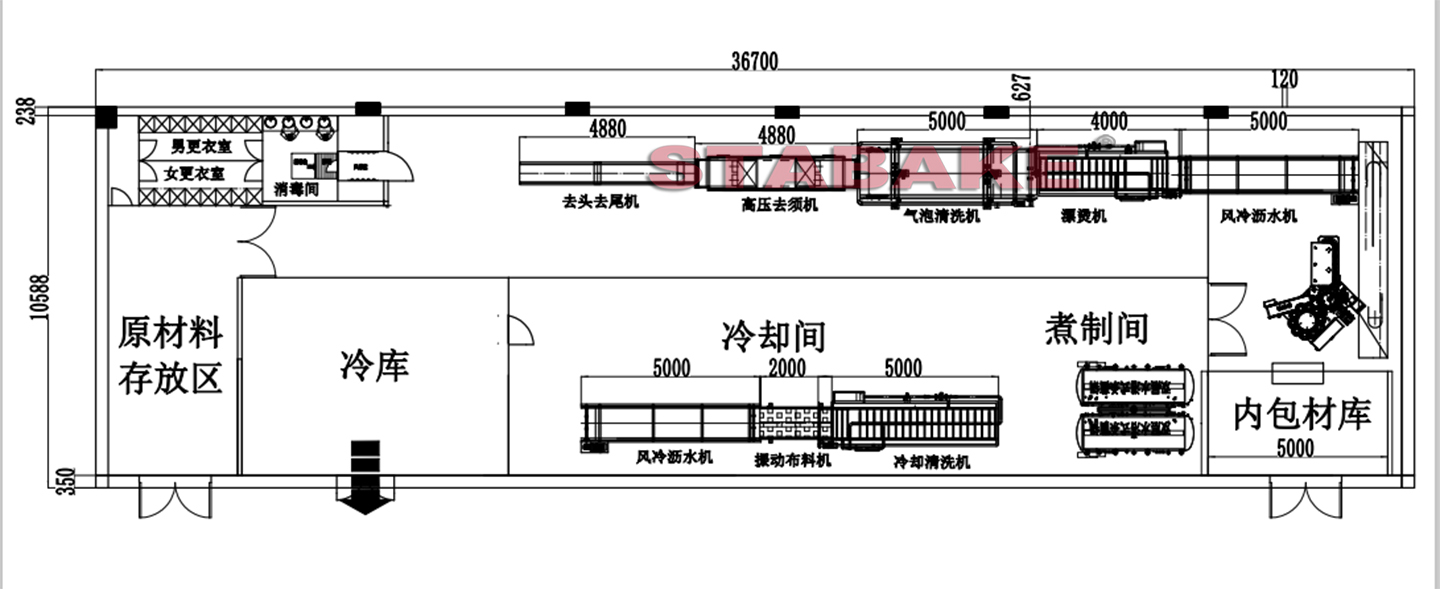

Ready-to-eat Hot Blanching Sweet Corn Processing Line

Processing Flow: Fresh sweet corn - Peeling husk - Cutting head and tail - Washing – Hot water blanching (remove enzymes and protect color) - Water Cooling - Draining and air drying - Vacuum packaging - High-temperature sterilization – Bag washing dehydration - warehousing

Equipment instruction:

☆ Corn head and tail trimming machine: The peeled corn sticks are manually placed neatly on the machine for head and tail trimming operations.

☆ Non damage sink lifting machine: The corn cobs with neat ends and tail ends enter the non damage lifting machine and are lifted to the hair removal cleaning machine. The non damage lifting machine is equipped with a buffer pool to protect the corn cobs from falling and colliding.

☆ Corn Hair Removal Cleaning Machine: Spray and clean the whiskers, insects, and soil on the surface of corn.

☆ Corn blanching and enzyme removal machine: Perform blanching, enzyme removal, and color protection on cleaned corn cobs.

☆ Water bath cooling machine: After blanching and color protection, the corn is cooled in a water bath. The next step is manual bagging operation.

☆ Bidirectional circulation bagging conveyor: manually carry out corn bagging operations on the bidirectional circulation conveyor, and use high-temperature sterilization special packaging bags to package corn.

☆ Vacuum Packaging Machine: Vacuum packaging operations are carried out on bagged corn cobs using the 1000 type corn special vacuum packaging machine.

☆ Packaging conveyor: The vacuum packaged corn enters the conveyor and is transported to the sterilization workshop for packaging and sterilization. (Optional)

☆ Fully automatic corn sterilization pot: After vacuum packaging of corn, high-temperature sterilization operation is carried out to further extend the shelf life of corn, using a water bath high-temperature sterilization pot.

Flip over air drying and water removal machine: Air drying and water removal operations are carried out on the surface moisture of vacuum packaged corn after sterilization, so that workers can pack and store it in storage.

Fresh sweet corn - Peeling husk - Cutting head and tail - Washing – High-Pressure Steam Sterilization Pot steaming - Water Cooling - Blast Freezing - Vacuum packaging

Processing Stages**

1. **Raw Material Reception & Inspection**

- Fresh corn cobs are delivered and inspected for quality (moisture content, maturity, defects).

2. **Husking & De-Kerneling**

- **Husking Machines**: Remove outer husks and silk from corn cobs.

- **De-Kerneling Machines**: Cut kernels from cobs using rotary blades, ensuring minimal damage.

3. **Cleaning & Washing**

- Kernels pass through vibrating screens and water jets to remove dirt, debris, and residual silk.

4. **Blanching**

- Kernels are briefly heated (90–100°C) in steam or hot water to:

- Inactivate enzymes that cause spoilage.

- Preserve color and texture.

5. **Cooling**

- Blanched kernels are rapidly cooled in chilled water to halt the cooking process.

6. **Grading & Sorting**

- Optical sorters or vibrating screens separate kernels by size, color, and defects.

7. **Individual Quick Freezing (IQF)**

- Kernels are conveyed through a **spiral freezer** or **fluidized bed freezer** (-30°C to -40°C), where they are frozen individually within minutes to prevent clumping and ice crystal formation.

8. **Packaging**

- Frozen kernels are weighed and packaged in plastic bags, pouches, or bulk containers using:

- **Automatic bagging machines** (with nitrogen flushing for extended shelf life).

- **Metal detectors** and **X-ray systems** to ensure safety.

9. **Cold Storage**

- Packaged corn is stored at -18°C or below until distribution.

Core Equipment in the Line**

- **Husking/De-Kerneling Machines**

- **Blanchers** (steam/hot water)

- **IQF Freezers** (spiral, tunnel, or fluidized bed)

- **Optical Sorting Systems**

- **Automated Packaging Systems**

- **Cold Chain Infrastructure**