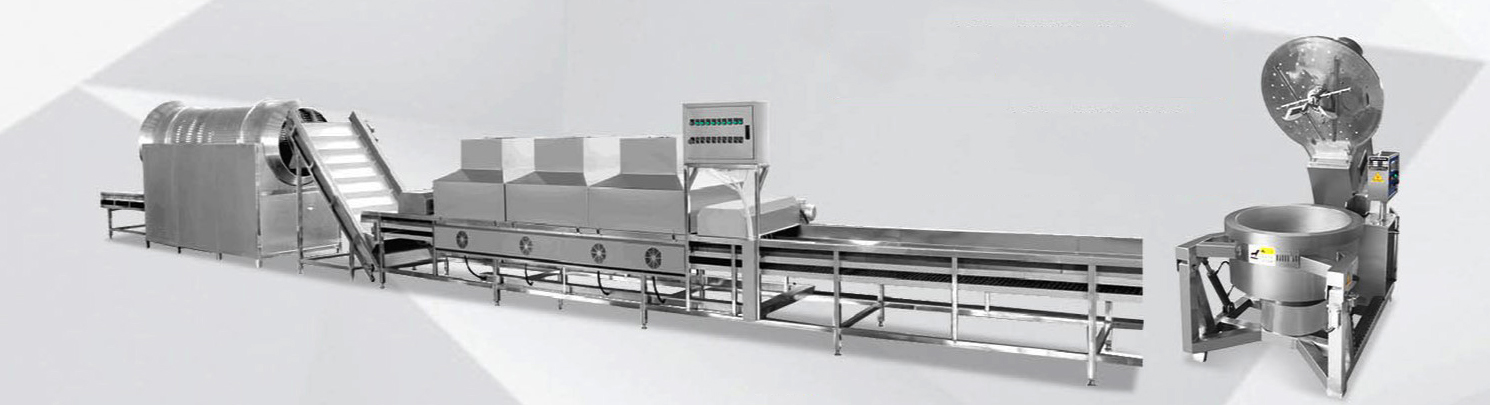

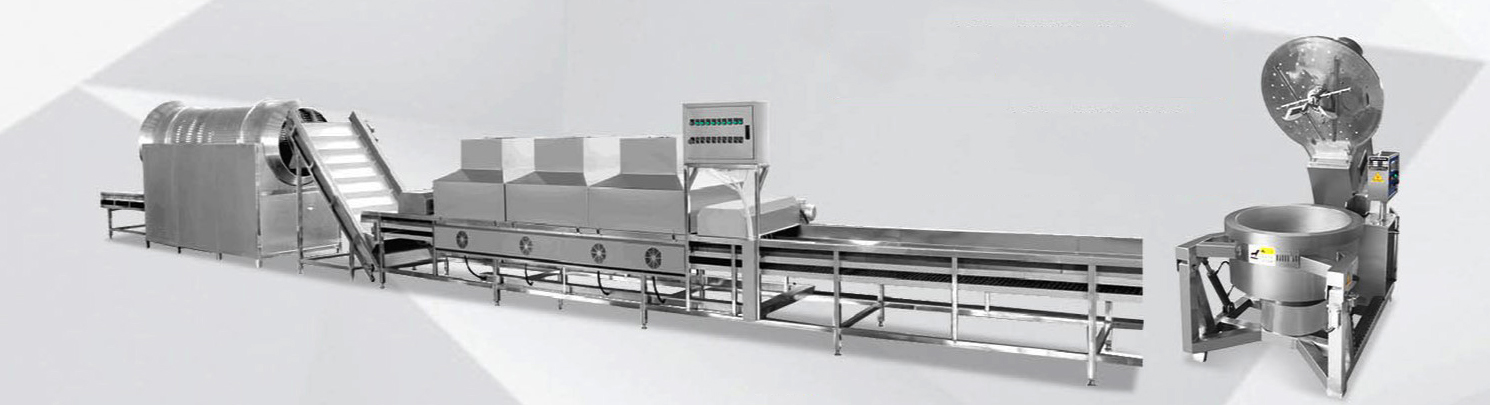

Commercial Popcorn Making MachineDescription

The spherical popcorn machine is a special equipment for frying spherical popcorn developed based on customer and market requirements on the basis of professional traditional planetary stirring woks. After careful research, excellent equipment modification, modified configuration, etc., it is energy-saving and hygienic. , high ball output efficiency, simple operation, fully intelligent and fully automatic one-button operation. Energy saving and environmental protection, no waste gas, waste residue and noise pollution. Heating is rapid, the instantaneous temperature can reach 280 degrees, making the corn burst instantly. It is safe to use and saves manpower. Models can be divided into 100L, 200L, 300L, 400L, 500L and other specifications according to the actual volume. Products with unconventional capacities can be processed and customized.

Feature

Popping time is short: the advanced combustion series and the pot material are well combined to shorten the corn popping time.

Multiple flavors can be produced in one pot: using variable frequency speed regulation to evenly mix corn, syrup and other flavor ingredients.

The sugar is evenly coated without smearing in the pot: It uses a combination of rotation and revolution to ensure that there are no blind spots in the pot.

The flower-shaped and ball shape popcorn can be made in one pot: and the bursting temperature of spherical corn can be reached in a short time, which effectively solves the problem of only popping corn on the market.

Discharge the popcorn instantly to avoid burning the pot and ensure the color and flavor of the popcorn.

Working Principle

The equipment is mainly composed of a pot body, a frame body, a stirring system, a heating system, a speed regulating transmission device, a stirring shaft, a pot turning system, etc. It adopts a hemispherical stainless steel pot body formed by one-time stamping, and uses liquefied gas, natural gas, steam , electromagnetic and other heating forms, the stirring method adopts a special tilt transmission, and the planetary stirrer used is in full contact with the pot body, achieving a non-integer transmission ratio of transmission revolution and rotation, so that there is no stirring dead zone in the pot. Using advanced transmission and sealing structures, the transmission part and the inside of the pot are clean and hygienic. Using variable frequency speed regulation power, the operation is more stable. It adopts hydraulic lifting, turning the pot and transporting materials, and does not need to disassemble and assemble the mixer, saving manpower and reducing labor intensity. It is a food processing equipment with excellent performance.