- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Automatic Belt Drying Machine

I. Description:

This equipment is a belt type muti-layer reverse dryer. The main parts are made of SUS304 stainless steel. The stainless steel mesh belt runs smoothly, it’s easy to maintain and has a long service life. The whole machine running speed and drying temperature can be set according to production needs. High-level of automation, saving labor and improving production efficiency.

The drying machine can be used not only for drying of Chinese herbal medicine such as white fungus, fungus, jujube, rhubarb, salvia miltiorrhiza, and ginseng, but also for dehydrated vegetables and fruit such as garlic, potato, onion, carrot, ginger, green pepper, apple, lemon,bamboo shoots, flowers, mushrooms, sweet potatoes, corn, peas, beans, coconuts, betel nuts, edible fungus and other air-permeable materials, it is widely range of applications in metallurgy, chemical industry, food, packaging fields, for drying of pieces, strip and granular materials with better air permeability, and especially suitable for the materials with high water content and high temperature. You can set the dryer temperature and humidity according to the actual material situation.

II. Working Principle:

1. The machine can use electric, gas, LPG, diesel, coal, biological pellet, and other energy heating. The working principle is that the steam generated by the heat source passes through the heat exchanger through the axial fan to transfer the hot air to the inside of the drying cabinet body, so that the moisture on the product is evaporated under the heat. Under the action of evaporating, the generated moist air discharged to the outside of the device with the tide pipe. The machine can continuously feed and make the material run smoothly. During material conveying process, the gap is conveyed through the intermittent mesh belt to realize turnover of the material and reach the homogeneity of the heated wind on all surfaces.It can connect with other equipment to achieve continuous operation.

2. Each unit of mesh belt dryer has independent circulation of hot air. Part of the tail gas is discharged by a special dehumidifying fan. The exhaust gas is controlled by a regulating valve. The hot air has the material up or down on the mesh belt. Heat dry and remove moisture. The mesh belt moves slowly, the operating speed can be adjusted freely according to the material temperature, and the dried product continuously falls into the receiver. Up and down cycle can be flexibly configured according to user needs, and the number of units can be selected according to the need. The amount of air, heating temperature, material residence time, and heating rate can be adjusted to achieve the drying effect.

3. Due to the low temperature of the material, the equipment is completely closed, only leaving the openings necessary for the discharge, and the effect of dehumidify is good.

4. The unique air intake device makes the distribution of hot air more uniform and ensures the consistency of product quality.

III. Technical Parameter:

Three-layer mesh belt drying machine | ||||||

Model | SC-1.2-8 | SC-1.2-10 | SC-1.6-8 | SC-1.6-10 | SC-2-8 | SC-2-10 |

Mesh belt width(m) | 1.2 | 1.6 | 2 | |||

Dry length(m) | 8 | 10 | 8 | 10 | 8 | 10 |

Thickness of the material(mm) | 10-50 | |||||

Temperature(℃) | 50-120 | |||||

Steam pressure(MPa) | 0.2-0.5 | |||||

Evaporation of water(kg/h) | 80-220 | 100-320 | 90-300 | 120-380 | 130-400 | 180-500 |

Steam consumption(kg/h) | ≦2kg Steam/evaporation of 1kg of water | |||||

Total power(kw) | 21.2 | 21.2 | 21.2 | 22.7 | 22.7 | 22.7 |

Size L*W*H (m) | 11*1.6*2 | 12.5*1.6*2 | 11*2.0*2 | 12.5*2.0*2 | 11*2.4*2 | 12.5*2.4*2 |

Total weight (kg) | 3000 | 4000 | 4400 | 4550 | 4300 | 6000 |

Five-layer mesh belt drying machine | ||||||

Model | WC-1.2-8 | WC-1.2-10 | WC-1.6-8 | WC-1.6-10 | WC-2-8 | WC-2-10 |

Mesh belt width(m) | 1.2 | 1.6 | 2 | |||

Dry length(m) | 8 | 10 | 8 | 10 | 8 | 10 |

Thickness of the material(mm) | 10-50 | |||||

Temperature(℃) | 50-120 | |||||

Steam pressure(MPa) | 0.2-0.5 | |||||

Evaporation of water(kg/h) | 100-250 | 120-350 | 110-320 | 140-400 | 150-450 | 200-550 |

Steam consumption(kg/h) | ≦2kg1 Steam/ evaporation of 1kg of water | |||||

total power(kw) | 21.2 | 21.2 | 21.2 | 22.7 | 22.7 | 22.7 |

Size L*W*H(m) | 11*1.6*2.7 | 12.5*1.6*2.7 | 11*2.0*2.7 | 12.5*2.0*2.7 | 11*2.4*2.7 | 12.5*2.4*2.7 |

Total weight (kg) | 3800 | 4780 | 4400 | 5550 | 5350 | 6800 |

Remarks | The machine size can Customized Manufacturing as demand. | |||||

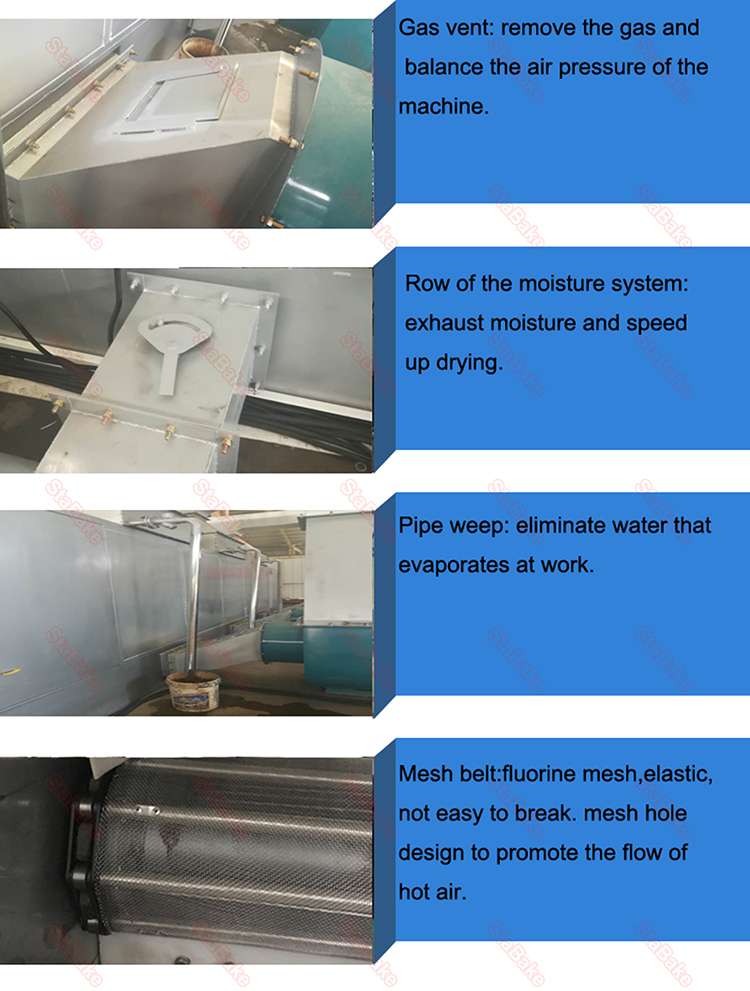

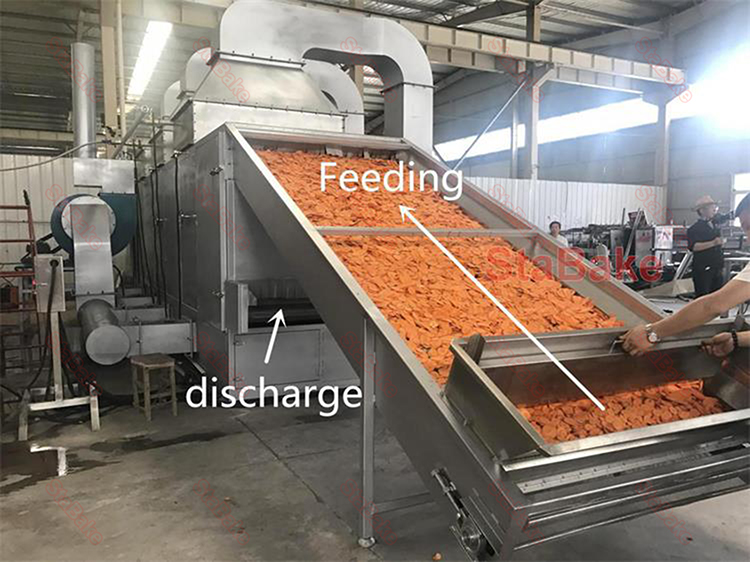

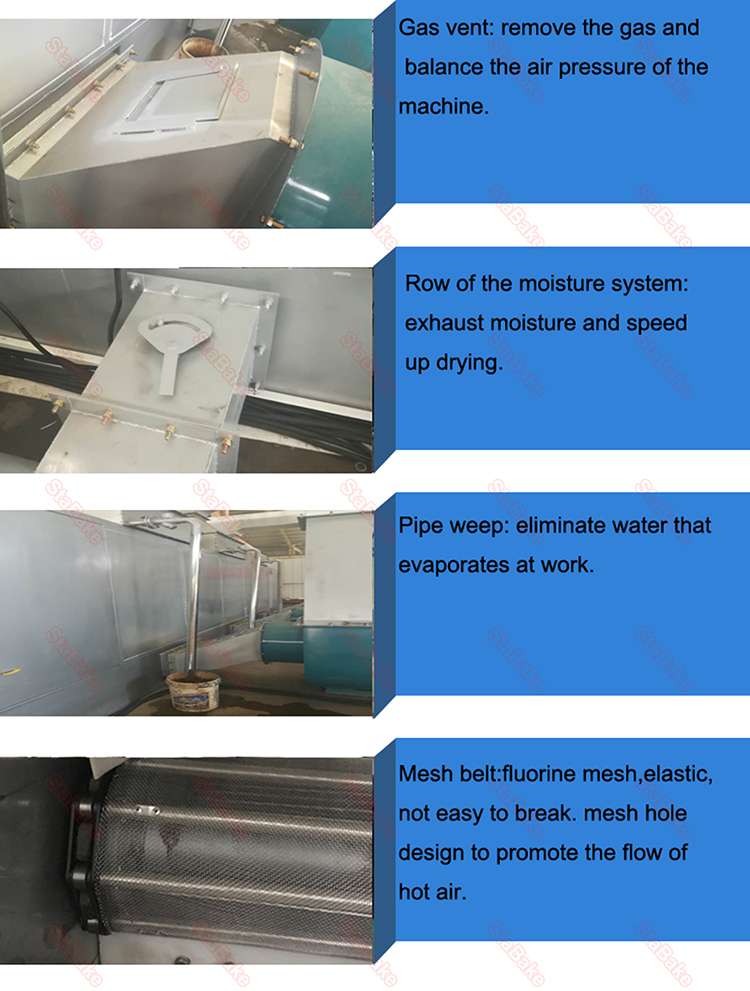

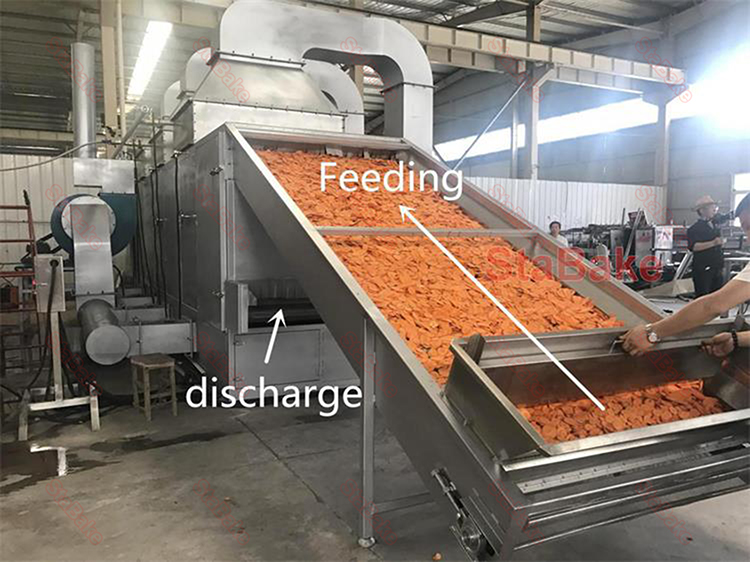

IV. Machine details:

V. Product Application:

Automatic Belt Drying Machine

I. Description:

This equipment is a belt type muti-layer reverse dryer. The main parts are made of SUS304 stainless steel. The stainless steel mesh belt runs smoothly, it’s easy to maintain and has a long service life. The whole machine running speed and drying temperature can be set according to production needs. High-level of automation, saving labor and improving production efficiency.

The drying machine can be used not only for drying of Chinese herbal medicine such as white fungus, fungus, jujube, rhubarb, salvia miltiorrhiza, and ginseng, but also for dehydrated vegetables and fruit such as garlic, potato, onion, carrot, ginger, green pepper, apple, lemon,bamboo shoots, flowers, mushrooms, sweet potatoes, corn, peas, beans, coconuts, betel nuts, edible fungus and other air-permeable materials, it is widely range of applications in metallurgy, chemical industry, food, packaging fields, for drying of pieces, strip and granular materials with better air permeability, and especially suitable for the materials with high water content and high temperature. You can set the dryer temperature and humidity according to the actual material situation.

II. Working Principle:

1. The machine can use electric, gas, LPG, diesel, coal, biological pellet, and other energy heating. The working principle is that the steam generated by the heat source passes through the heat exchanger through the axial fan to transfer the hot air to the inside of the drying cabinet body, so that the moisture on the product is evaporated under the heat. Under the action of evaporating, the generated moist air discharged to the outside of the device with the tide pipe. The machine can continuously feed and make the material run smoothly. During material conveying process, the gap is conveyed through the intermittent mesh belt to realize turnover of the material and reach the homogeneity of the heated wind on all surfaces.It can connect with other equipment to achieve continuous operation.

2. Each unit of mesh belt dryer has independent circulation of hot air. Part of the tail gas is discharged by a special dehumidifying fan. The exhaust gas is controlled by a regulating valve. The hot air has the material up or down on the mesh belt. Heat dry and remove moisture. The mesh belt moves slowly, the operating speed can be adjusted freely according to the material temperature, and the dried product continuously falls into the receiver. Up and down cycle can be flexibly configured according to user needs, and the number of units can be selected according to the need. The amount of air, heating temperature, material residence time, and heating rate can be adjusted to achieve the drying effect.

3. Due to the low temperature of the material, the equipment is completely closed, only leaving the openings necessary for the discharge, and the effect of dehumidify is good.

4. The unique air intake device makes the distribution of hot air more uniform and ensures the consistency of product quality.

III. Technical Parameter:

Three-layer mesh belt drying machine | ||||||

Model | SC-1.2-8 | SC-1.2-10 | SC-1.6-8 | SC-1.6-10 | SC-2-8 | SC-2-10 |

Mesh belt width(m) | 1.2 | 1.6 | 2 | |||

Dry length(m) | 8 | 10 | 8 | 10 | 8 | 10 |

Thickness of the material(mm) | 10-50 | |||||

Temperature(℃) | 50-120 | |||||

Steam pressure(MPa) | 0.2-0.5 | |||||

Evaporation of water(kg/h) | 80-220 | 100-320 | 90-300 | 120-380 | 130-400 | 180-500 |

Steam consumption(kg/h) | ≦2kg Steam/evaporation of 1kg of water | |||||

Total power(kw) | 21.2 | 21.2 | 21.2 | 22.7 | 22.7 | 22.7 |

Size L*W*H (m) | 11*1.6*2 | 12.5*1.6*2 | 11*2.0*2 | 12.5*2.0*2 | 11*2.4*2 | 12.5*2.4*2 |

Total weight (kg) | 3000 | 4000 | 4400 | 4550 | 4300 | 6000 |

Five-layer mesh belt drying machine | ||||||

Model | WC-1.2-8 | WC-1.2-10 | WC-1.6-8 | WC-1.6-10 | WC-2-8 | WC-2-10 |

Mesh belt width(m) | 1.2 | 1.6 | 2 | |||

Dry length(m) | 8 | 10 | 8 | 10 | 8 | 10 |

Thickness of the material(mm) | 10-50 | |||||

Temperature(℃) | 50-120 | |||||

Steam pressure(MPa) | 0.2-0.5 | |||||

Evaporation of water(kg/h) | 100-250 | 120-350 | 110-320 | 140-400 | 150-450 | 200-550 |

Steam consumption(kg/h) | ≦2kg1 Steam/ evaporation of 1kg of water | |||||

total power(kw) | 21.2 | 21.2 | 21.2 | 22.7 | 22.7 | 22.7 |

Size L*W*H(m) | 11*1.6*2.7 | 12.5*1.6*2.7 | 11*2.0*2.7 | 12.5*2.0*2.7 | 11*2.4*2.7 | 12.5*2.4*2.7 |

Total weight (kg) | 3800 | 4780 | 4400 | 5550 | 5350 | 6800 |

Remarks | The machine size can Customized Manufacturing as demand. | |||||

IV. Machine details:

V. Product Application:

Whatsapp/ Wechat: 0086-18560205581

Whatsapp/ Wechat: 0086-18560205581